There are two main types of pollutants that need to be filtered by Teflon microporous filter membrane in compressed air. One is atmospheric pollution that is sucked into the compressor. Objects, 80% of which have a diameter of less than 2 μm; the other is the material carried out by the compressor, which is in the form of smoke and dissipates into aerosols of 0.01~0.8 μm.

General filtration can remove most liquid and solid matter particles, the particle size of which is generally greater than 1μm, and it is necessary to remove very small particles. Tiny solid particles and oil and water aerosols require the use of high-efficiency filters, which is technically complex. As far as its methods and mechanisms are concerned, it is impossible to make any strict physical classification. For example: Gravity separation, centrifugal separation, inertial impact, direct interception, Brownian diffusion, eddy current, diffusion, thermal condensation, electrostatic precipitation, magnetic precipitation, Brownian condensation, acoustic condensation, turbulent flow precipitation. In certain situations, for a particular type of particle, only one mechanism plays a leading role, but most of them The situation is the combined effect of multiple mechanisms.

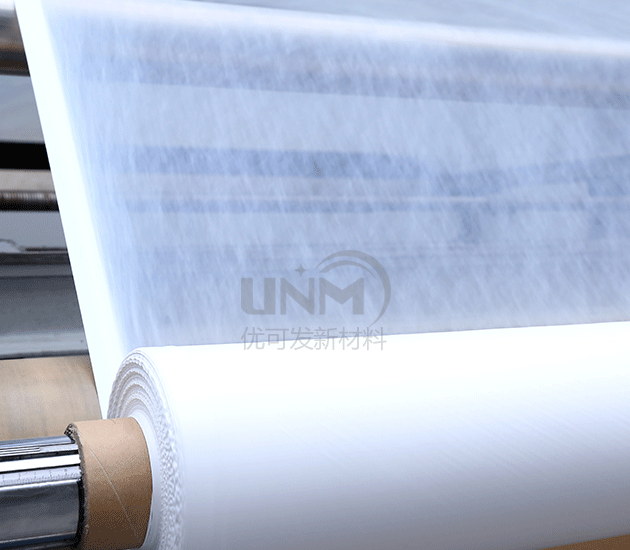

PTFE microporous membrane manufacturer’s Teflon microporous filter membrane has a surface filtration mechanism that can easily remove dust. The pore size is small and uniform, the micropore structure is stable, the porosity can reach 80%~90%, the filtration efficiency can reach 99.999995%, and the filtration accuracy can reach above U15 level, or even reach U17 level.

Teflon microporous filtration membrane The manufacturer has a series of mature core technologies such as PTFE membrane manufacturing, modification and compounding. The performance of the PTFE membrane produced has reached a very high level in the industry. It has begun to challenge and gradually replace industry giants such as Daikin and Nitto Denko in the market. Interested parties can enter the store for consultation and purchase!

</p