Expanded polytetrafluoroethylene membrane with a special microporous structure is usually stretched and shaped at high temperature to create a microporous structure, which can Processing membrane materials below 1 mm, and the thickness requirements of expanded polytetrafluoroethylene (ePTFE) membranes are usually between 4 and 12 mm, so superimposed bonding is generally used to bond sheets with some thickness. In addition, expanded polytetrafluoroethylene (ePTFE) membrane can also be bonded with other materials to meet the needs of different uses.

The filter uses microporous filter membrane with uniform pore size distribution as the filter material. Microporous filter membranes are divided into two types: hydrophilic and hydrophobic. The material of the filter membrane depends on the nature of the filtered items and the purpose of filtration.

The pore size of filter membranes used in pharmaceutical production generally does not exceed 0.22μm. The pore size of a filter is defined by the filter’s retention of microorganisms, rather than the distribution coefficient of the average pore size. Therefore, it is necessary to select a stage filter with experimental proof of retention for subsequent filters.

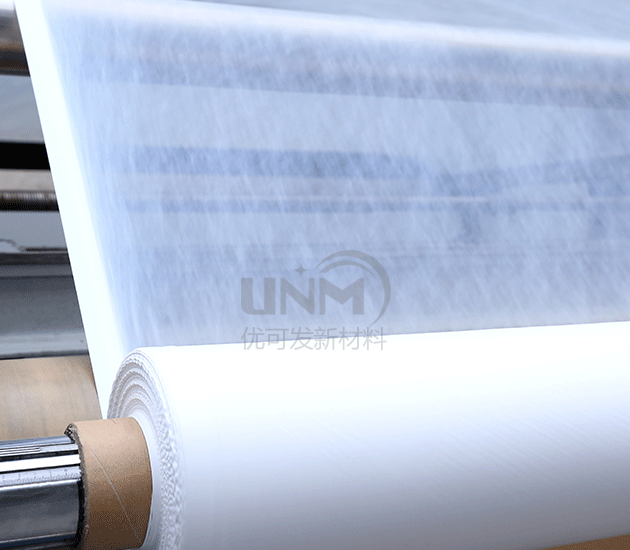

Expanded polytetrafluoroethylene membrane is made of polytetrafluoroethylene (PTFE) resin through special processing such as biaxial stretching and turning. Made by this method, while maintaining the excellent chemical properties of PTFE, different functions and uses can be achieved by changing the structure, shape, thickness, surface geometry of the material, and then matching it with auxiliary materials with different characteristics. The manufacturing and processing of ePTFE membrane mainly involves two levels of core processes: stretching process and modification and composite processing.

Expanded polytetrafluoroethylene membrane technology has always been the core of business, in biopharmaceuticals, equipment, food and beverages, semiconductors It plays an indispensable role in many fields such as manufacturing and communications. Its pore-forming capacity ranges from 0.1μm to 1μm, providing functional solutions such as fine filtration, removal of small bacteria and viruses, hydrophobic breathability, and sound transmission. Interested parties can enter the store for consultation and purchase!

</p