Bacteria filtration verification includes two parts: performance confirmation of the filter itself and filtration process verification. The performance confirmation of bacterial filtration membrane itself is generally produced by the filter Completed by the supplier, the filtration process verification is implemented based on the specific media to be filtered and combined with specific process conditions. Validation of filtration processes generally includes bacterial retention tests, chemical compatibility tests, extractables or leachables tests, reliability assessment and adsorption assessment, etc.

To truly ensure the feasibility of the filtration process, it is not enough to just choose a suitable filtration product. It needs to be based on actual conditions. The filtration process undergoes a series of verification work. How to carry out filtration process verification well? This requires filter users to clearly understand what type of filter should be used and how to use the filter correctly.

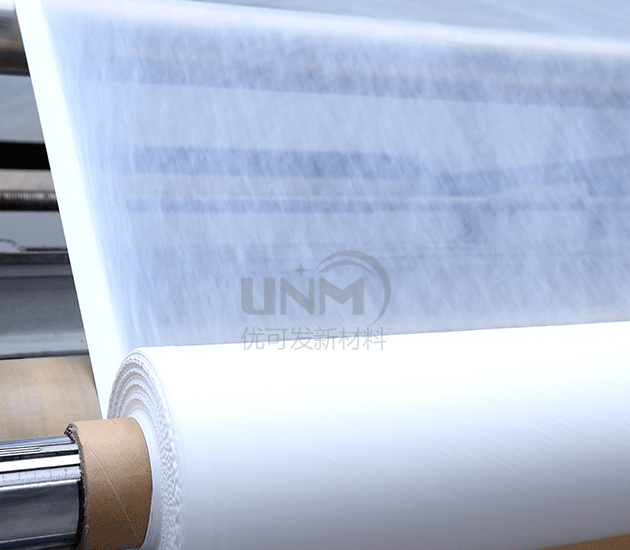

PTFE film manufacturer specializes in the production of bacterial filtration membrane. It has a full set of advanced production equipment and technology, and also has advanced clean rooms and The independent composite slitting workshop ensures the production quality of Bacterial Filtration Membrane; the product materials produced are all imported raw materials, with high uniformity, stable performance, good air permeability, and the filtration efficiency can reach 99.999995%! It can basically meet the filtration efficiency grade requirements of sub-high efficiency, high efficiency and ultra high efficiency filters. The company has a full set of advanced production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. Interested parties can enter the store for consultation and purchase.

</p