Polytetrafluoroethylene (ptfe), this material has excellent high temperature resistance, alkali resistance, hydrophobicity and non-adhesive properties. This material is widely used in air purification, industrial dust removal, pharmaceutical fields, electronic appliances, clothing fields, etc.

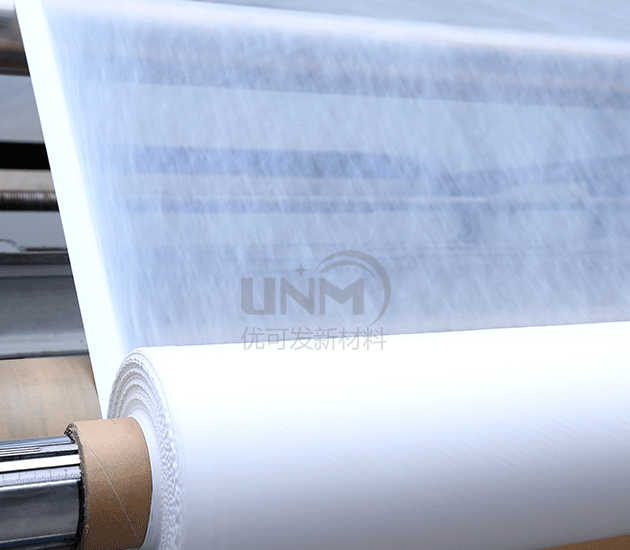

Polytetrafluoroethylene film is made of ptfe resin by molding and sintering , Cooling formed film, the film turned into a non-oriented film, it has no breathable function, but has water-repellent function! Currently, it is widely used in industrial and marine fields such as chemical industry, petroleum, textile, food, papermaking, medicine, electronics and machinery.

PTFE coating has significant heat resistance stability, and the heat resistance temperature can reach 320℃ in a short time, generally between -190℃~260℃ ℃ can be used continuously, it will not be brittle when cooled at low temperatures, and will not melt when heated at high temperatures. PTFE coatings have strong physiological inertness. Except for individual media, such as fluorinated media, molten alkali and molten alkali metals, they are almost insensitive to any chemicals, such as strong acids, strong alkali, strong oxidants, reducing agents and organic Solvent corrosion can protect parts from various corrosions.

Polytetrafluoroethylene filmThe manufacturer has a series of mature core technologies such as PTFE membrane manufacturing, modification and compounding, and produces The performance of PTFE membrane has reached a very high level in the industry. It has begun to challenge and gradually replace industry giants such as Daikin and Nitto Denko in the market. In the future, the company will continue to maintain stable investment in R&D, build barriers to core technologies for product updates and iterations, assist in the breakthrough and localization of key technologies in domestic industries, solve the problem of upstream core raw materials being choked by foreign countries, and strive to provide Leading customers in various industries provide polytetrafluoroethylene films. Interested parties can enter the store for consultation and purchase!

</p