PTFE membrane, also known as polytetrafluoroethylene membrane, is a polymer material with excellent chemical stability and temperature resistance. It can be widely used in acid-alkaline membrane fuel cells, electrodeposition, electroanalysis and other fields.

Acid-alkaline membrane fuel cell is a type of fuel cell that is currently widely studied, and its core component is the proton membrane. It has excellent proton transfer properties and can transfer hydrogen ions from the negative electrode to the positive electrode, thereby generating electrical energy. Compared with traditional alkaline membrane fuel cells, fuel cells have the advantages of fast response, good stability, and long service life. They can also be used for electrodeposition and electroanalysis. During the electrodeposition process, PTFE proton membrane can separate and enrich ions, thereby achieving fine electrodeposition. In the field of electroanalysis, it can be used as an electrolyte to analyze the content and concentration of different ions in the sample by measuring the diffusion rate of protons on the proton membrane.

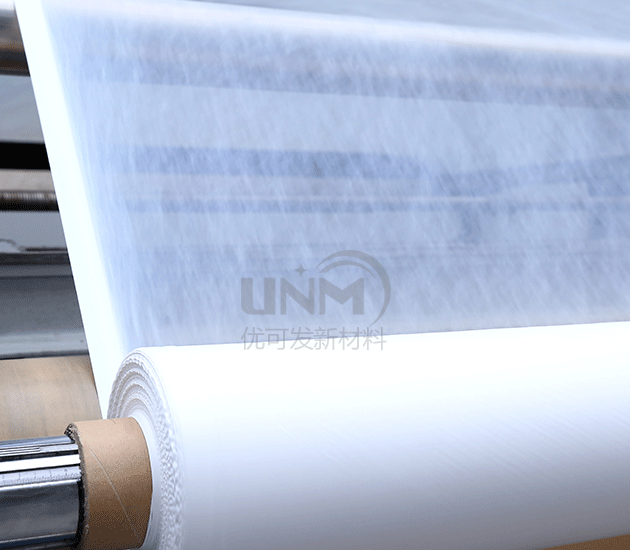

The advantage of PTFE proton membrane lies not only in its excellent chemical stability and temperature resistance, but also in its special microstructure. The PTFE molecular chains are arranged in an orderly manner in the crystal region to form elongated grains, and in the amorphous region they form a uniform glassy phase. This microstructure allows the film to have a high degree of crystallinity and a low melting point, allowing it to maintain good physical properties.

It is a PTFE proton membrane material manufacturer that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, operating temperature, etc., online control of thickness and void ratio can be achieved based on the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation.

</p