On June 9, the Ningbo Municipal Ecological Environment Bureau issued an announcement on the acceptance of the PTA unit product transformation and upgrading technical transformation project of Zhejiang Yisheng Petrochemical Co., Ltd. The main contents are as follows:

Zhejiang Yisheng Petrochemical Co., Ltd. was established in 2003. It is mainly engaged in the production of purified terephthalic acid (PTA). Since its establishment, it has completed four phases of projects. , has built four sets of PTA production units, with the designed production capacities of each unit being 530,000 t/a (Phase 1), 530,000 t/a (Phase 2), 1.5 million t/a (Phase 3), and 1.5 million t/a respectively. a (Phase IV), the total designed production capacity of the entire plant is 4.06 million t/a. Due to market and other reasons, the PTA unit of the second phase project has been suspended since the end of 2013.

In order to meet the market demand for PIA, Yisheng Petrochemical plans to implement the “Zhejiang Yisheng Petrochemical Co., Ltd. PTA unit product transformation and upgrading technology transformation project”. The total investment in this project is 350.85 million yuan. The existing discontinued phase II PTA production unit will be transformed, and the main equipment and pipelines will be updated to meet the demand for the production of refined isophthalic acid (PIA), forming an annual output of 300,000 tons of refined isophthalic acid. Production capacity and public works mainly rely on existing related facilities. After the transformation is implemented, this set of equipment will no longer produce PTA products.

Overcapacity brings an end to PTA’s booming era!

I remember that from 2015 to 2016, the main logic of market operations at that time was to frame the operating range of PTA based on processing fees. This was a special product of the industry clearing stage in the context of overcapacity. Later, PTA entered a boom cycle due to the postponement of production capacity, and the logic of operating according to the processing fee became less important.

Since 2019, the PTA market has shown an overall downward trend, with prices falling from around 6,500 yuan at the beginning of the year to around 4,800 yuan at the end of the year, a drop of more than 25%. Entering 2020, an unexpected epidemic swept across the country, and both domestic futures and stock markets plummeted. After the holidays, the domestic epidemic has not yet ended. Enterprises’ resumption of work and transportation are restricted. The chemical market is facing a waterloo, and the PTA market has fallen to a four-year low.

In addition to external factors, from a fundamental perspective, the prominent contradiction between supply and demand is also the main reason for the market crash. Since 2019, the domestic PTA industry has embarked on its second concentrated expansion period in history. The growth rate of PTA production capacity is much greater than the growth rate of polyester production capacity, and PTA will once again be in surplus. The processing range will be compressed to a lower range again, and the idea of operating according to the processing fee will once again return to the public eye.

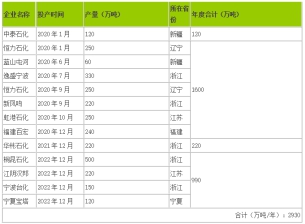

Table 1 2020-2022 PTA device production plan

According to public information, it is expected that PTA will usher in a new round of production capacity launch cycle from 2020 to 2022. By the end of 2022, PTA has a total production capacity launch plan of 29.3 million tons. The new production capacity will mainly come from leading downstream companies. With the expansion of raw material matching and PTA’s main suppliers, the expansion of PTA production capacity will lead to a reshuffle of the industrial supply pattern, and the era of high prosperity will come to an end.

At present, large domestic enterprises such as Tongkun, Rongsheng, Hengli, Hengyi, Shenghong, Sanfangxiang and Xinfengming are still adding or acquiring polyester products. production capacity, and at the same time extending its industrial chain to the upstream raw material industry, its ability to be self-sufficient is getting stronger and stronger. However, the equipment scale, technical level and scale of traditional enterprises (except for individual equipment) are obviously lagging behind private enterprises in all aspects. Their competitiveness is at a disadvantage and they have eliminated production capacity. The continuous commissioning of new production capacity by private enterprises will rapidly reduce the market share of polyester raw materials (PX, PTA, MEG) of traditional enterprises. Therefore, some PTA companies are changing production based on this consideration.

Import dependence reaches 85%! The conversion to PIA production brings a glimmer of hope to the surplus PTA industry

Isophthalic acid, also known as PIA (some people call it IPA), is a white crystalline powder or needle crystal. Easily soluble in alcohol and glacial acetic acid, slightly soluble in boiling water but insoluble in cold water, almost insoluble in benzene and petroleum ether. Industrially, isophthalic acid is produced by using m-xylene as the raw material, cobalt acetate as the catalyst, acetaldehyde as the accelerator, and acetic acid as the solvent at low temperature liquid phase oxidation at 120°C under a pressure of about 0.6MPa. In addition, hydrolysis of isophthalonitrile or oxidation of m-xylene with potassium permanganate is also an industrial method for producing isophthalic acid.

PIA has strong heat resistance, hydrolysis resistance and chemical resistance. It is used in alkyd resin coatings, polyester (PET) resin, unsaturated (UPR) resin, special It has preventive uses in fiber, hot melt adhesive, printing ink, polyester fiber dyeing modification, resin plasticization and medicine.

In 2018, domestic PIA import dependence reached 85%. And based on the total domestic PIA import volume in the past ten years, it still shows a relatively obvious upward trend. The huge supply gap in the PIA industry has brought a glimmer of hope to the sluggish PTA industry, and some companies have started to upgrade their equipment.

1. In August 2018, Jialong Petrochemical plans to install a 600,000 tons/year PTA device , to carry out the PIA project of converting production to 250,000 tons/year.

2. Yizheng Chemical Fiber 350,000 tons/year PTUnit A is converted to produce PIA.

3. On April 3, 2019, Zhejiang Yisheng Petrochemical Co., Ltd. implemented the “PTA unit product transformation and upgrading technical transformation” on the existing PTA second-phase production unit and made an environmental impact assessment announcement. . The second phase of the PTA production unit (with an annual output of 700,000 tons of PTA) will be transformed, using high-temperature liquid phase technology, to produce 350,000 tons/year of PIA products.

4. In July 2017, Taihua Industrial (Ningbo) Co., Ltd.’s new 200,000-ton PIA project passed the environmental impact assessment. The project adopted medium-temperature oxidation and hydrogenation refining process technology.

A large number of new devices are about to be put into production, and PIA is not far away from overcapacity!

According to incomplete statistics, as of the end of 2019, the global PIA production capacity totaled 2.35 million tons. In 2019, multiple domestic and foreign devices were put into production, with production capacity increasing by approximately 35%. In early January, Indorama’s 340,000-ton unit in the United States was put into commercial operation. In May, an old 40,000-ton unit at Japan’s Mitsubishi was restarted. At the end of December, news came about that Yangzi Petrochemical’s 250,000-ton unit was put into operation. This device is my country’s second PIA device. After it was put into operation, my country’s PIA production capacity increased from 50,000 tons to 300,000 tons.

In addition to Yangzi Petrochemical, domestic projects under construction, Ningbo Yisheng and Yizheng Chemical Fiber PIA reconstruction projects are about to be completed, and Ningbo Formosa Plastics and Fujian Jialong’s new 200,000-ton installations are also speeding up. under construction. The total production capacity of these four units is as high as 1.2 million tons. If put into production as scheduled in 2020, China will become the world’s largest PIA production center. Internationally, the 380,000-ton new plant of South Korea’s Lotte, which ranks first in total production capacity, has been completed. The 200,000-ton m-xylene plant was put into operation as early as 2018. It is expected that the plant is more likely to be put into operation in early 2020. All in all, the PIA market will suffer more severe pressure from the supply side next year.

Due to the expansion of global production capacity, domestic PIA imports reached a new level in 2019. Customs data shows that PIA imports reached 320,000 tons from January to November 2019, and imports for the whole year are expected to reach 340,000 tons, a year-on-year increase of approximately 11.5%. The main importing places are still the main production places such as Taiwan, South Korea and Japan. In 2019, my country’s apparent consumption of PIA was approximately 390,000 tons. The market has already shown a surplus, and it is expected that it will be difficult to digest more products. If South Korea’s Lotte goes into production first in 2020, imports may continue to grow. However, once domestic projects under construction are put into operation, domestic import dependence will drop significantly, and at the same time, the market will also face a collapse, because most of these manufacturers are equipped with complete downstream equipment. , it is difficult to compete with imported goods. Of course, after the domestic market is oversupplied, it will be difficult to open the export market in the short term and compete with international giants.

Finally, from the demand side, PIA is mainly used as an additive to produce unsaturated polyester resin (UPR), polyester resin and alkyd resin, but the dosage is not high. Moreover, after 2019, the climax of capacity expansion of major downstream polyester may come to an end, and the growth of PIA demand will also be subject to certain restrictions.

In summary, despite the sluggish PIA trend in 2019, the market is still relatively optimistic. However, a large number of new devices are about to be put into production, and the domestic market The day of overcapacity is not far away. Competition in the industry will intensify in the future, the prospects are bleak, and the market may usher in a truly dark period. </p