Affected by the new round of epidemic in India, the epidemic has broken out again in Southeast Asia and other countries. The manufacturing industry may be hit again as a result, and the global supply chain is facing a new round of tests. As a major producer and exporter of natural rubber, Malaysia has initiated a 14-day lockdown. Although the lockdown does not involve port terminals, the reduction in port operation efficiency partially affects the shipping business. The intensification of shipping delays may affect some rubber exports to China, but the volume is limited. India and Vietnam, major textile exporters, have been severely affected by this round of epidemic, causing some “short-term, small and bulk” European and American orders to return to China. The substitution effect is obvious in the short term, but the extent to which China can benefit depends on India and Vietnam. How long will the epidemic last?

Malaysia is in lockdown, and shipping delays are aggravating or affecting rubber exports

Malaysia will start from June A two-week comprehensive blockade will be implemented on January 1. Although this blockade does not involve ports, the efficiency of port operations and terminal operations will be reduced, especially for trade activities passing through the Strait of Malacca, which will have a certain negative impact.

A shipping company stated that after Malaysia’s “lockdown”, the shipping business will definitely be affected, and its port business volume may be reduced to 60%, increasing port congestion and delaying shipping schedules. The phenomenon intensified. Some traders reported that the shipping schedule was delayed for more than a week, which caused a chain reaction of rising sea freight and a shortage of containers. Another shipping company stated that the impact of the country’s lockdown on shipping has been limited, and its ports are still operating normally, and the transportation cycle has been around 15-20 days during the epidemic. As the world’s major natural rubber producer and exporter, Malaysia’s export volume to China may be partially affected, but based on the current operation of Penang Port, the impact may be limited.

Malaysia is an important country with energy and chemical resources. Its main products include palm oil, rubber, oil and natural gas, etc. It is the second largest producer of palm oil and related products and the third largest liquefied oil producer in the world. Natural gas exporting countries, etc. Among them, 17.8% of China’s oil products (including palm oil) come from Malaysia.

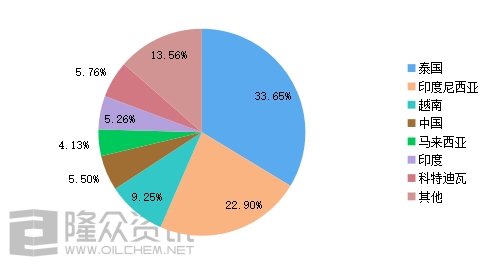

Take natural rubber as an example. Malaysia is the fifth largest natural rubber producer and exporter in the world, accounting for nearly 4.13% of the world’s output. Among them, nitrile gloves account for more than 60% of global production, making it the world’s largest producer.

Proportion of global natural rubber production in major producing countries

And Nearly 13% of China’s natural rubber imports come from Malaysia, ranking third among its import source countries. Customs data shows that imports from Malaysia in April were around 75,400 tons.

Distribution of natural rubber import sources in 2020

Judging from the current production situation of natural rubber in Malaysia, it is understood that most rubber companies have not been affected. A local natural rubber manufacturer said that the company is currently maintaining normal production, and the impact is mainly reflected in downstream terminal glove factories. In terms of exports, judging from the operation situation of Penang Port, the new outbreak of the epidemic has intensified the tightening of epidemic prevention measures. The number of port staffing has been reduced. The reduction of operating efficiency may lead to the recurrence of terminal congestion and the phenomenon of delayed shipping. Intensification is possible, but the impact on exports to China is expected to be limited.

The textile industry in India and Vietnam has been affected by the epidemic

With the outbreak of the epidemic in Southeast Asia, more than half of India’s The local government has chosen to “close the city”, and some industrial parks in Bac Giang and Bac Ninh provinces in Vietnam have been temporarily closed. Many pillar industries in the two countries are facing severe impact, and the textile and clothing industry, which is mainly labor-intensive, has borne the brunt.

According to reports, industry insiders in the Indian garment export industry said that due to the new round of epidemic, related Indian companies have lost a large number of garment export contracts due to the inability of workers to come to work. Dinesh Kataria, a textile trader in Surat, India, said that there are 65,000 textile traders in Surat. If calculated according to the average number, the textile industry in Surat is losing at least US$48 million every day. The export volume of the hosiery industry center located in Ludhiana, a city in the northern Indian state of Punjab, decreased by 35%. Relevant data shows that in the major garment towns of Delhi and Bangalore, the absenteeism rate of garment industry workers is as high as 50%. Industry insiders said that this time of year is usually the peak ordering period, but now buyers from all walks of life are more cautious.

At present, India has become the world’s largest cotton producer, the world’s largest jute producer, and the world’s second largest silk producer. Its yarn production capacity accounts for 22% of the world’s. The textile and apparel industry is one of the leading market segments of the Indian economy and one of India’s largest sources of foreign exchange earnings. The textile industry accounts for about 15% of India’s total export revenue.

Vietnam, known as the world’s second factory, has the textile industry as one of its most important national pillar industries. Its second largest export industry, with exports accounting for approximately 12% of the country’s GDP, has created a large number of jobs (accounting for more than 20% of the industrial workforce and 5% of the total labor force). According to data from Vietnam Customs, affected by the COVID-19 epidemic, Vietnam’s textile and clothing exports in 2020 reached US$35.69 billion, down 9.9% from 2019. Even so, against the background of a 25% decline in the global textile industry, Vietnam’s textile exports still rose to the second place in the world.

Some textile orders return to China, and the short-term substitution effect is obvious

Under the influence of the new round of epidemic, manufacturing in India and Vietnam has frequently stalled. For labor-intensive products represented by textiles, the substitution effect is more obvious in the short term. Some textile orders have been transferred to China, but The quantity is limited.

Currently, after May Day, some European and American weaving orders with short delivery times return to China, mostly “short-term, small and bulk” orders .The sales person in charge of a certain weaving company said that during Labor Day, a small number of European and American orders were received. Such orders usually have short delivery times and small quantities. He also said that they are only received by individual companies.

Some economists pointed out that the resurgence of the epidemic in Asia is beneficial to China’s manufacturing industry. However, the extent to which China can benefit depends on how long the epidemic lasts in India and Vietnam. Refer to the return of Southeast Asian orders in 2020 Judging from the situation, with the effective control of the epidemic in the later period, there is a high probability that such orders will quickly return from China to Southeast Asia.

So far, China’s textiles and clothing have maintained rapid growth. According to customs statistics, from January to April this year, the country’s textiles and clothing exports were US$88.371 billion, a year-on-year increase of 32.65%. Among them, textile exports were US$43.956 billion, a year-on-year increase of 17.81%; clothing exports were US$44.415 billion, a year-on-year increase of 51.54%. In the month of April, China’s clothing exports were US$11.123 billion, a year-on-year increase of 65.03%, and the export growth rate continued to increase by 22.9 percentage points compared with the previous month. Compared with the same period before the epidemic (April 2019), exports increased by 19.4%.

</p