Waterproof Oxford cloth can be made breathable or non-breathable according to different uses.

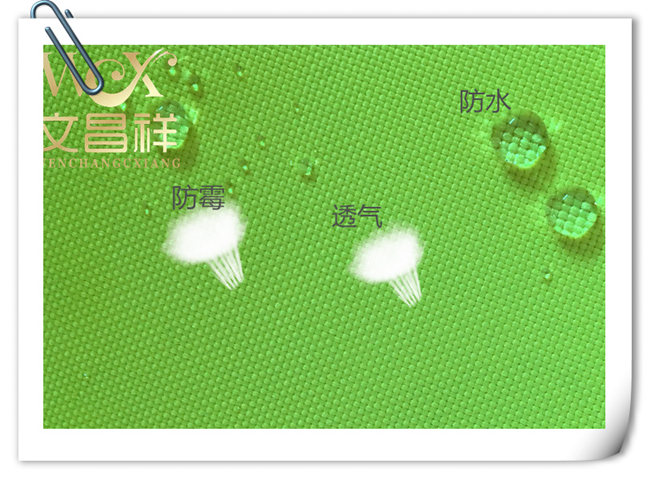

210D Oxford The cloth should be made of plain weave interwoven on a water-jet loom, with a density of 15×19, a yarn count of 200D, and a width of 150CM. 210D Oxford cloth has fine texture and light texture. After coating, waterproofing and some post-processing, it has the advantages of soft feel, waterproof, breathable, and good durability.

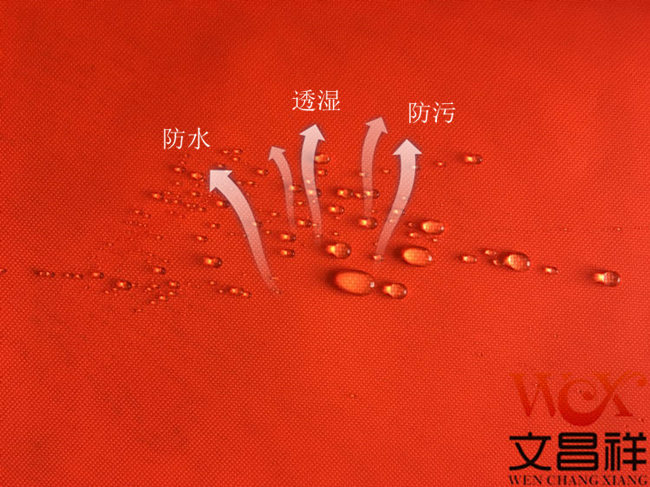

420D Oxford The cloth is woven from 400Dx400D polyester silk, plain weave. Density and weight can be customized according to needs. The density in the picture above is 20×24, the weight is 210, and the door width is 150CM. After dyeing, finishing, waterproofing, PVC coating and other treatments, 420D Oxford cloth has bright colors, breathable, waterproof, fireproof, sunscreen, UV protection, mildewproof, wear-resistant and other properties. It is suitable for advertising tents, carports, awnings, outdoor tents, etc.

210D Oxford Compared with 420D Oxford cloth, it does not have the advantages of wear resistance and low tear resistance, but it also has the excellent properties of Oxford cloth. 210D Oxford cloth is used in tents, luggage linings, hotel shower curtains, cosmetic bags, bags, advertising aprons and other places with low friction.

Make every meter of cloth with care–Textilehttp://www.wcxfz.com

</p