pp environmentally friendly flame retardant

What is pp environmentally friendly flame retardant?

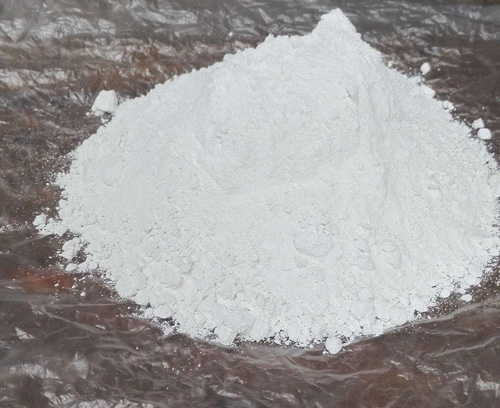

PP environmentally friendly flame retardant is different from halogen-containing flame retardants. During the combustion process, it achieves the purpose of heat insulation, air isolation and flame retardancy by producing a dense expanded carbon layer without irritating hydrogen halide gas and black smoke. It is a An environmentally friendly flame retardant.

PP environmentally friendly flame retardant is a kind of flame retardant specially used for polypropylene plastics. PP environmentally friendly flame retardant is a halogen-free, intumescent flame retardant specially developed for polypropylene. It is polymerized by synergistic phosphorus-containing and nitrogen-containing chemicals. It has good compatibility in polypropylene, has little impact on the mechanical properties of plastics, and has excellent processing stability during processing. m7k5hVcM

Formaldehyde-free flame retardant pure cotton fabric finishing

PyrovatexCP uses hydroxymethyl as a reactive group to cross-link with fibers. At the same time, in order to improve the flame retardant efficiency and make the fabric have sufficient phosphorus content and durability, a cross-linking agent containing hydroxymethyl reactive groups needs to be added during use. The hydroxymethyl group easily decomposes and releases formaldehyde, causing formaldehyde to exceed standards in the production environment and finished fabrics. Since various countries require that textiles produced and imported do not contain toxic and polluting substances, it is urgent to develop formaldehyde-free flame retardant products.

At present, the durable flame retardants for natural fibers are tetrahydroxymethylphosphonium chloride (THPC) from British Allbrigh & tWilson Company and N-hydroxymethyl-3-(dimethoxyphosphono)propionamide ( PyrovatexCP) is the representative. However, THPC uses formaldehyde during the synthesis process and produces bischloromethyl ether, which is carcinogenic. Therefore, the European Union has introduced regulations to restrict its use.

In this experiment, environmentally friendly flame retardant GM-1 was synthesized using dimethyl methyl phosphonate, phosphorus pentoxide, and pentaerythritol as the main raw materials. Flame retardant GM-1, cross-linking agent citric acid/maleic acid (the material ratio is 1:1) compound acid, and catalyst sodium hypophosphite were used to perform flame retardant finishing on cotton fabrics. The flame retardant, The influence of the dosage of cross-linking agent and catalyst and baking conditions on the flame retardant effect.

1 Test

1.1Materials and instruments

Fabric: Pure cotton bleached plain cloth 21tex×21tex (Weifang Longdu Cotton Textile Printing and Dyeing Co., Ltd.)

Drugs: dimethyl methylphosphonate (Yangzhou Chenhua Technology Group Co., Ltd.), phosphorus pentoxide (Zhangjiagang Feiyu Chemical Co., Ltd.), pentaerythritol (Shanghai Kefeng Chemical Reagent Co., Ltd.), triphenyl phosphite, octanoic acid Stannous (Sinopharm Chemical Reagent Co., Ltd.), citric acid (Wujiang Changli Chemical Co., Ltd.), maleic acid (Shanghai Zhuoyue Chemical Co., Ltd.), sodium hypophosphite (Shanghai Lingfeng Chemical Reagent Co., Ltd.)

Instruments EHP350MM fine-tuned horizontal rolling mill (British ROACHES Company), YG815B vertical method fabric flame retardant performance tester (Nantong Sansi Electromechanical), 101-1 electric constant temperature blast drying oven (Shanghai Hualian Environmental Testing Equipment Co., Ltd.), TY800 Series breaking strength tester (Jiangdu Tianhui Testing Machinery Co., Ltd.), MZ-12 fully automatic washing machine (Shanghai Jiangfeng Garment Machinery Factory)

1.2 Flame retardant synthesis process

In a reactor equipped with a stirrer, thermometer, dropping funnel and condenser, add 142g of dimethyl methylphosphonate, heat to 50~55°C, then add 150g of phosphorus pentoxide, and adjust the reaction temperature to 90 ~95℃, insulation reaction for 3 hours. Cool the reactant to 50~55°C, add 15g of triphenyl phosphite, and keep it warm for 2 hours. Continue to heat the reaction mixture to 70~75°C, add 70g of pentaerythritol and 0.2g of catalyst stannous octoate, and keep the reaction at 75~85°C for 5 hours. The product obtained is a bright yellow transparent liquid.

1.3 Fabric flame retardant finishing process

Treatment process: padding finishing solution (two padding and two padding, rolling residue rate 100%~110%)→prebaking (120℃×1.5min)→baking (170℃×3min)

Process prescription

Flame retardant GM-1/g 400

Compound acid/g60

Sodium hypophosphite/g30

Add deionized water to /L1

1.4Performance Test

1.4.1 Combustion performance

Measured with reference to GB/T5455-1997 “Vertical Method for Textile Combustion Performance Test”.

1.4.2 Breaking strength

Referring to GB/T3932.1-1997 “Tensile Properties of Fabrics Part 1: Determination of Breaking Strength and Elongation at Break”, measure the weft direction of the sample 5 times, take the average value, and calculate the fabric breakage according to formula (1) Strong loss rate:

In the formula: W0——the breaking strength of the fabric after finishing;

W1——The breaking strength of the fabric before finishing.

1.4.3 Washing resistance

Measured with reference to AATCC124-2005 “Appearance of Fabrics after Repeated Home Laundering”.

2. Results and discussion

2.1 Dosage of flame retardant

The amount of flame retardant is an important factor in controlling the finishing effect. Under the same other treatment conditions, the effect of flame retardant dosage on the flame retardant properties and breaking strength of pure cotton fabrics is shown in Table 1.

It can be seen from Table 1 that as the amount of flame retardant increases, the flame retardant properties of cotton fabrics increase, the breaking strength decreases, and the loss rate increases. When the dosage reaches 400g/L, the flame retardant performance is basically stable and the loss of breaking strength slows down. This is because when performing flame retardant finishing on pure cotton fabrics, polycarboxylic acids are added as cross-linking agents. When the amount of flame retardant is low, the flame retardants establish intermolecular ester bonds with polycarboxylic acids and cellulose macromolecules. It is fixed on the fabric, so that the flame retardancy increases with the increase of its dosage. Since the reactive groups on polycarboxylic acids and cellulose macromolecules are the same,Of course, when the dosage of flame retardant exceeds 400g/L, the flame retardant has fully reacted with polycarboxylic acid and cellulose macromolecules. If the dosage of flame retardant is increased, the change in flame retardant performance will no longer be obvious. After flame retardant finishing, due to the introduction of a certain number of cross-linking bonds between the basic structural units and macromolecules of the fiber, the activities between the structural units of the fiber are subject to certain restrictions, and the burden of external forces is greater than that of untreated fabrics. Unevenness will cause the strength to decrease and the fracture strength loss rate to increase. When the cross-linking bonds reach a certain number, the magnitude of the decrease in strength becomes smaller and the loss of fracture strength slows down. After comprehensive consideration, the dosage of flame retardant is determined to be 400g/L.

Note: Cross-linking agent 60g/L, catalyst 30g/L, baking temperature 180℃, baking time 3min.

2.2 Polycarboxylic acid concentration

The cross-linking agent can condense itself into a network structure during the flame retardant process, and can also cross-link with cellulose macromolecules. It can also condense with the flame retardant to form stable chemical bonds and be fixed on the fiber, greatly improving the washability. This test uses citric acid/maleic acid compound acid with a substance ratio of 1:1 as the cross-linking agent. The effect of the compound acid dosage on the flame retardant properties and breaking strength of pure cotton fabrics is shown in Figure 1.

It can be seen from Figure 1 that when the dosage of polycarboxylic acid is 60g/L, the flame retardant effect is better and the carbon length is shorter. Continuing to increase the amount of flame retardant, the flame retardant effect is not improved significantly, the carbon length does not change much, and the fracture strength loss rate increases significantly. Comprehensive consideration, the appropriate dosage of polycarboxylic acid is 60g/L.

2.3 Catalyst concentration

In order to quickly react and cross-link the flame retardant and cross-linking agent with fiber macromolecules during the baking process, an appropriate amount of catalyst needs to be added to the flame retardant formula to shorten the reaction time, improve the flame retardant effect, and reduce damage to the cellulose. degree. This test uses sodium hypophosphite as the catalyst. The effects of catalyst dosage on the flame retardant properties and breaking strength loss rate of pure cotton fabrics are shown in Table 2.

It can be seen from Table 2 that as the catalyst concentration increases, the flame retardant effect improves. However, adding too much catalyst will cause the pH value of the finishing solution to be too low, which will actually reduce the strength of the fabric. After comprehensive consideration, the dosage of catalyst sodium hypophosphite was determined to be 30g/L.

2.4 Baking conditions

After the fabric was treated with the same process (flame retardant dosage 400g/L, cross-linking agent dosage 60g/L), it was baked at different temperatures for 3 minutes. The effects of temperature on the flame retardant properties and breaking strength of pure cotton fabrics are shown in Table 3. .

It can be seen from Table 3 that as the baking temperature increases, the flame retardant properties of cotton fabrics gradually increase, but the fabric breaking strength loss also increases. The choice of baking temperature depends on the reaction between flame retardants and cross-linking agents, as well as the cross-linking reaction between them and cellulose macromolecules. If the temperature is low, the flame retardant effect will be poor. If the temperature is too high, it will easily cause excessive loss of fabric strength. After comprehensive consideration, the baking temperature is determined to be 180°C.

The experiment was carried out by changing the baking time at 180℃. The results are shown in Figure 2.

It can be seen from Figure 2 that when the baking temperature is 180°C, as the baking time increases, the burning char length of the cotton fabric becomes shorter and the flame retardant performance continues to improve, but the strength of the fabric decreases. After comprehensive consideration, the baking time is determined to be 3 minutes.

2.5 Flame retardant performance

The optimization process determined above is adopted, that is, flame retardant 400g/L, cross-linking agent 60g/L, catalyst 30g/L, baking temperature 180°C, and baking time 3 minutes to treat pure cotton fabrics. The relevant test indicators are shown in Table 4. .

(1) The flame retardant finishing optimization process of pure cotton fabrics using self-made flame retardants is: flame retardant GM-1400g/L, cross-linking agent citric acid/maleic acid (the ratio of the amount of substances is 1:1) 60g /L, catalyst 30g/L, baking temperature 180℃, baking time 3min.

(2) The pure cotton fabric treated by the optimized process has a burning carbon length of only 10.2cm after 50 washes, and has good flame retardancy.

(3) The synthesized flame retardant GM-1 does not contain formaldehyde, and formaldehyde-containing additives are not used during the finishing process, so it can be regarded as an environmentally friendly product.

As can be seen from Table 4, after 50 washes of the pure cotton fabric treated with the optimized process, the burning char length is only 10.2cm, indicating that the flame retardant GM- has good flame retardancy and durability. jJ1uxK9iQqhRv

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA