Overview

For more than 100 years, regenerated cellulose fiber has been deeply loved by consumers for its good hygroscopicity, antistatic properties and good coloring properties. Before the 1970s, viscose fiber, one of the regenerated celluloses, was once a major variety of chemical fiber producers. However, with the emergence and development of new varieties of synthetic fibers, and the long and complicated production process of viscose fiber, which consumes a lot of energy and water, it has caused serious environmental pollution. The treatment of waste gas and sewage is difficult and expensive. Largely, some developed countries have closed down some factories producing viscose fiber, causing their output to drop by about 41% in 20 years.

However, foreign manufacturers and scientific researchers have not given up on research on regenerated cellulose fibers. Scientists from various countries are working hard to find a method that can be directly dissolved with solvents to produce cellulose fibers to reduce environmental pollution but not lack fiber. Characteristics of plain fiber. This is the study of solvent-spun cellulose fibers.

1. Development of new solvent-spun cellulose fibers

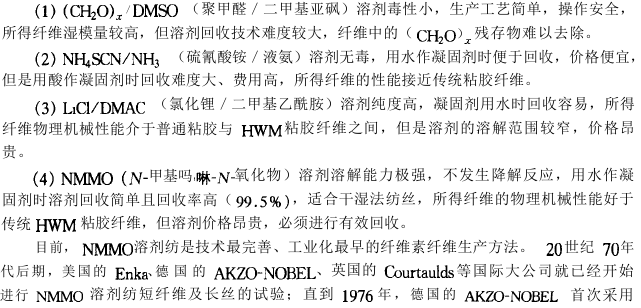

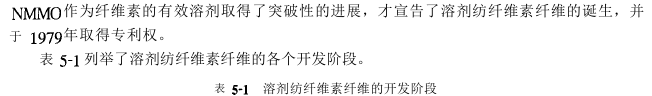

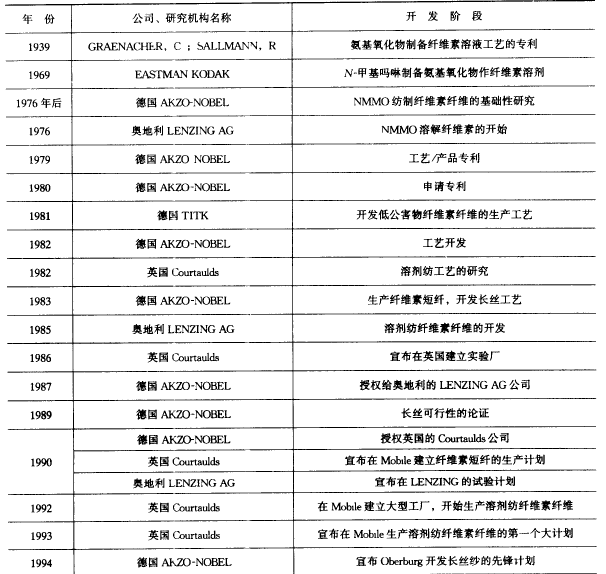

Research on solvent-spun cellulose fibers began in 1939. For decades, scientists have searched for and tested a variety of direct solvents for cellulose. However, from the perspective of industrialization, the following cellulose solvents have important industrial significance.

AAASDFWFWFWE

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA