At present, my country’s non-woven fabric production has been developing rapidly, especially in recent years, with spunbond technology Mainly imported spunbond filament non-woven equipment and production capacity are showing a rapid growth trend.

Filter materials have become an indispensable and important product in modern society. As a new type of filter material, non-woven filter materials are gradually replacing traditional textile filter materials and becoming the leading product of filter media due to their unique three-dimensional network structure, uniform pore distribution, good filtration performance, low cost and many varieties. Extremely fast.

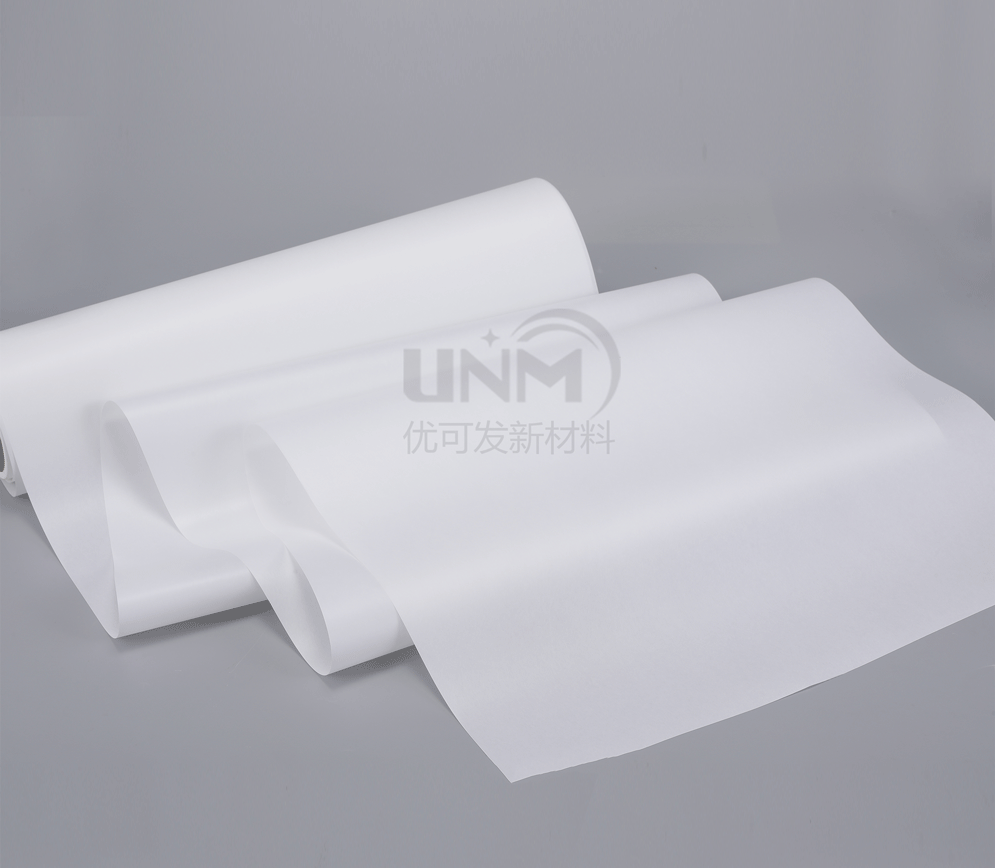

Imported spunbond filament non-woven fabric is a kind of non-woven fabric. To put it simply: it is not intertwined and braided together by yarns one by one, but the fibers are directly bonded together through physical or chemical methods. It has high strength, small difference in vertical and horizontal strength, is resistant to aging, has a melting point of 164~170°C, and the product can be sterilized at temperatures above 100°C. It has the characteristics of no deformation at 150℃ without being affected by external force.

Imported spunbond filament non-woven fabrics for sale can be widely used in air filtration, packaging materials, medical tapes, cable wrapping, biofilms and other fields. We have a complete pre-sales, sales and after-sales service system. Undertake various filter material coating processing services. Our company will perform coating processing according to the coating substrate provided by the customer or the coating substrate specified by the customer. The key to its technology is the optimized combination of speed ratio, pressure ratio, operating temperature and other parameters. Our company can realize online control of air permeability, thickness and void ratio according to the ratio and pore-forming medium to meet the different needs of users. Interested parties can enter the store to inquire and purchase! </p