At present, the existing air filters and membranes on the market generally have low filtration efficiency and poor quality factor. Low, safety hazards caused by electret failure and low capture efficiency of ultra-fine particles, etc. Therefore, there is an urgent need to develop an efficient and low-cost air filtration membrane, and the PTFE air filter membrane came into being.

Non-woven fabrics are very common in life. When used as filters, they can only filter large particles such as dust and sand. They cannot filter odors, droplets, toxic and harmful gases, PM2.5, etc. , has basically been eliminated by mainstream manufacturers, and is currently the lowest-end product on the market.

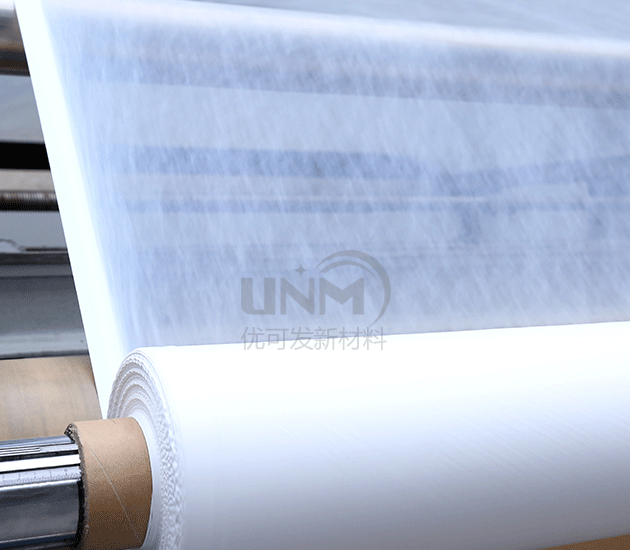

PTFE air filter membrane is made by special processes such as mixing, extrusion, extrusion, calendering, and biaxial stretching. Moreover, the pore size of the material is small and the distribution is concentrated, achieving surface filtration to achieve a dust removal efficiency of 99.9%~99.999%. For some extremely fine particles with a diameter of 0.1um-0.3um, it can better prevent fine dust from entering the filter material. It can operate at a continuous operating temperature of 240°C and an instantaneous temperature of 260°C.

It is a fluorine material film manufacturer integrating production, sales and customization. The company has advanced PTFE air filter membrane production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. We have a complete pre-sales, sales and after-sales service system. Interested parties can enter the store to consult us. </p