Teflon microporous membrane has special properties that other materials do not have, making it suitable for use in many fields It has advantages that traditional materials do not have.

The membrane separation process is a method of separating mixtures using membranes. As a selective phase between two phases, the membrane can allow one or more components of the two phases to pass through the membrane and intercept other components, thereby achieving separation between different components and achieving separation, concentration and purification. For the purpose, it mainly uses the fluid pressure difference as the driving force for the screening and separation process.

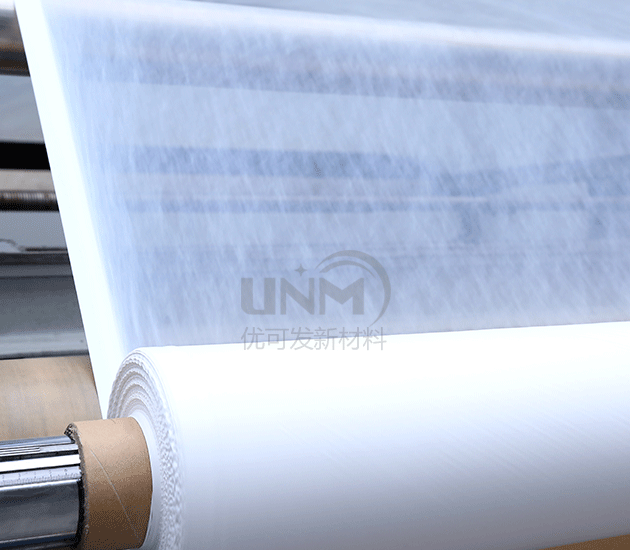

The environmentally friendly filter material Teflon microporous membrane has significant results in purifying the air. The product is made by mechanically stretching PTFE material, which can ensure the complete interception of impurities such as bacteria and has a large flux. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. Therefore, the microporous membrane has good waterproof properties and good breathability, so it is very suitable for waterproof, dustproof and breathable applications.

It is a manufacturer of polytetrafluoroethylene (ptfe) membrane environmentally friendly materials that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the key parameters of Teflon microporous membrane technology such as speed ratio, pressure ratio, operating temperature and other parameters, online control of air permeability, thickness and porosity can be achieved based on the ratio and pore-forming medium to meet your needs. of different requirements. Interested parties can enter the store for consultation. </p