PTFE bubble point membrane is a flexible and elastic microporous material. Due to its Its various advantages and good performance are often used by people in all walks of life, bringing great help to people’s production and manufacturing.

The liquid “sterilization filtration” process in the strict sense means that because the product is unstable, final sterilization methods including heat sterilization that are approved by regulatory authorities cannot be used, and instead A method of filtration sterilization and a process that requires the filtrate to be sterile. Due to the inherent high risk in sterility assurance, the new version of GMP, like the international pharmaceutical production regulatory regulations, pays great attention to sterilization filtration.

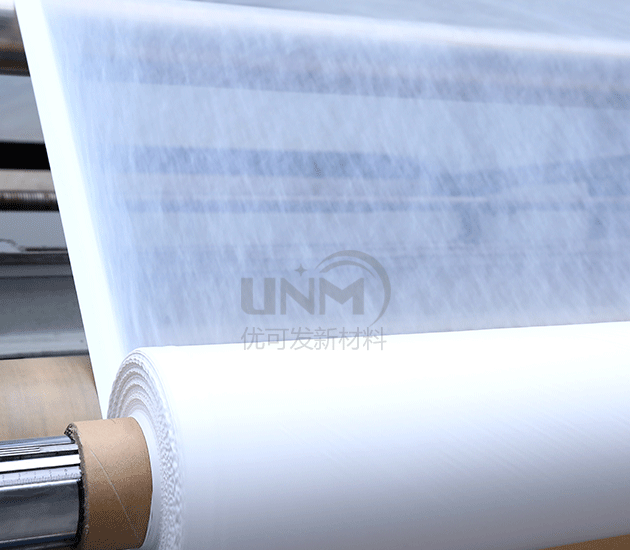

PTFE bubble-point membrane has a fibrillar microporous structure with a porosity of more than 88%, 1.4 billion micropores per square centimeter, and a pore size range of 0.1μm-0.5μm. This film is made with a special process Coated on various fabrics and substrates, it can become a new type of filter material. The membrane has small pore size, uniform distribution, and large porosity. While maintaining air circulation, it can filter all dust particles including bacteria to achieve advanced purification. and ventilation purposes.

It is a manufacturer of environmentally friendly polytetrafluoroethylene bubble film materials that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation. </p