In recent years, the latest developments in material technology have continuously improved the protective performance of medical masks. This includes the use of polytetrafluoroethylene mask membranes to improve filtration performance, enhance antibacterial performance and improve wearing comfort.

Medical surgical masks: Standard surgical masks are generally composed of 3-4 layers. The outer layer is waterproof and can prevent droplets from entering the mask. The middle layer functions as a filter, and the inner layer close to the mouth and nose is used to absorb moisture. Ensure wearer’s lips are dry and comfortable. Filter elements generally use ultrafine fibers as melt-blown nonwoven materials. The ultrafine fibers are randomly arranged to form a large number of tiny pores.

The polytetrafluoroethylene mask membrane is a purely physical barrier and does not rely on static electricity. When the user inhales, the pore size of 100~200 nanometers will pass through the physical screening of PM2.5 to PM0.3. Blocked on the surface of the mask, with the help of the super self-lubricating characteristics of the polytetrafluoroethylene material, every time you exhale, the particles attached to the surface of the mask will be pushed back into the environment. This repeats without relying on electrostatic adsorption. It truly achieves effective PM2.5 protection effect.

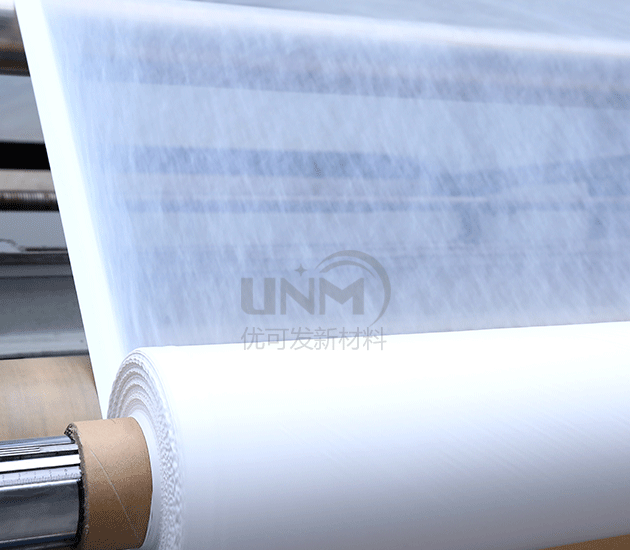

The polytetrafluoroethylene mask membrane produced has strong hydrophobicity, chemical resistance, waterproofness and low wind resistance, and can achieve high dust removal efficiency. For some diameters of 0.1um-0.3 um extremely small particles, the filtration level can reach H13-U16. In addition, the biaxially stretched film can undoubtedly achieve ultra-low emissions in intercepting various types of dust generated during the company’s production process, and it fully complies with current environmental protection standards. Interested parties can enter the store to inquire and purchase! </p