In the context of environmental protection where energy conservation and emission reduction are being advocated all over the world, solar energy, as a new energy source with the fastest development speed and the greatest potential, has received support from policies and funds. Today we will learn about this material from eptfe waterproof breathable membrane manufacturer.

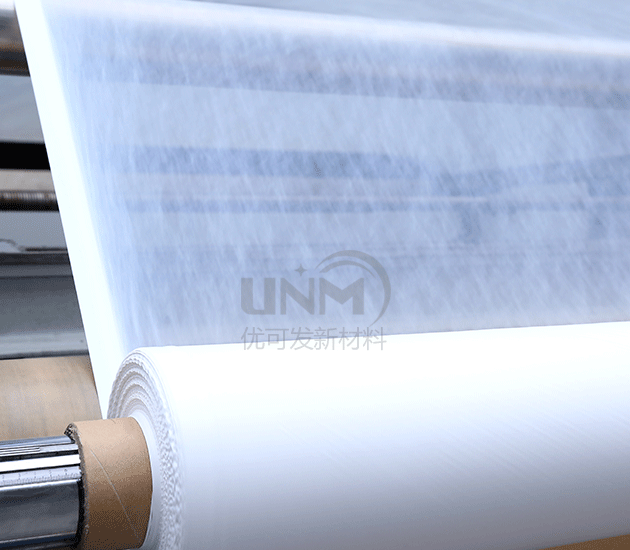

The technology of waterproof and breathable membranes was first introduced from European and American countries. However, the production processes of domestic products are diverse, and the quality of products from various manufacturers is uneven, and a unified quality standard has not been formed. In fact, waterproof and breathable membranes mainly consist of three layers: PP spunbond non-woven fabric, PE polymer breathable membrane, and PP spunbond non-woven fabric.

The technology of waterproof and breathable membranes was first introduced from European and American countries. However, the production processes of domestic products are diverse, and the quality of products from various manufacturers is uneven, and a unified quality standard has not been formed. In fact, waterproof and breathable membranes mainly consist of three layers: PP spunbond non-woven fabric, PE polymer breathable membrane, and PP spunbond non-woven fabric.

eptfe waterproof breathable membrane manufacturer‘s polytetrafluoroethylene microporous membrane is obtained by biaxial stretching of a polymer compound of tetrafluoroethylene. It has the highest corrosion resistance in the world today* One of the best materials, except for a few chemicals such as chlorine trifluoride and liquid chlorine, it is resistant to all other chemical reactions, is insoluble in strong acids, strong alkali, and organic solutions, and does not change in boiling nitrohydrochloric acid. The temperature resistance range is -195℃~250℃, and the long-term use temperature is -100℃~250℃.

Eptfe waterproof breathable membrane manufacturer specializes in the production of polytetrafluoroethylene microporous membranes. It has a full set of advanced production equipment and technology, and also has advanced clean rooms and independent composite points. The cutting workshop ensures the production quality of PTFE membrane; the product materials produced are all imported raw materials, with high uniformity, stable performance, good air permeability, and the filtration efficiency can reach 99.999995%! It can basically meet the filtration efficiency grade requirements of sub-high efficiency, high efficiency and ultra high efficiency filters. Interested parties can enter the store for consultation and purchase!

</p