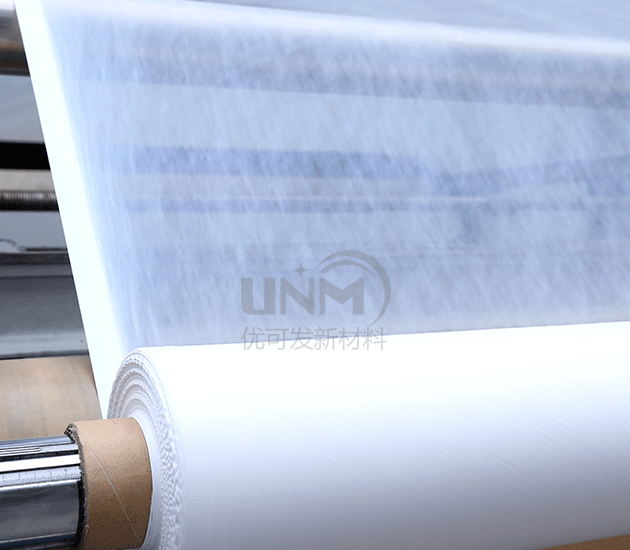

Waterproof sound-permeable membrane for phones and watches It is a microporous membrane made of polytetrafluoroethylene as raw material and using a special process through calendering, extrusion, and biaxial stretching. It has the characteristics of high peel strength, large air permeability, and uniform pore size distribution.

The real waterproof and breathable membrane is not compounded with glue, so its temperature resistance is -40,100 degrees (EU CE standard, US ASTM standard). It is not produced with polyethylene or TPO coating, so the air permeability should exceed 1500g/square/24 hours. If it is produced with polyethylene or TPO coating, it is basically not breathable. Hydrostatic pressure testing shows that the hydrostatic pressure of a thin waterproof and breathable membrane is at least 1.5 meters, and that of a thick waterproof and breathable membrane is at least 2 meters.

Waterproof sound-permeable membrane for phones and watches It has a microporous structure with staggered fibers and has been heat-set at high temperatures. The microporous structure is very stable and can effectively intercept dust particles. Moreover, the pore size of the material is small and the distribution is concentrated, achieving surface filtration to achieve a dust removal efficiency of 99.9%~99.999%. For some extremely fine particles with a diameter of 0.1um-0.3um, it can better prevent fine dust from entering the filter material. It can operate at a continuous operating temperature of 240°C and an instantaneous temperature of 260°C.

The waterproof sound-permeable membrane for phones and watches produced by the manufacturer uses imported raw materials, has a full set of advanced production equipment, an advanced clean room and an independent composite branch. The cutting workshop ensures the production quality of PTFE film; it uses production testing instruments imported from the United States to test the quality of PTFE film, and has passed international SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us.

</p