TeflonWaterproof breathable membrane is a new type of polymer waterproof material. In terms of production technology, the technical requirements of this waterproof and breathable membrane are much higher than those of ordinary waterproof materials. The main functions of the waterproof and breathable membrane are: waterproof, dustproof, and breathable.

The process of spray glue or squeegee lamination (hot melt glue lamination) was first used in sanitary napkins, diapers, and protective clothing. At present, almost all domestic manufacturers use this process to produce highly breathable waterproof and breathable materials. The disadvantage is that the air permeability is relatively low, because the micropores of the middle breathable film are actually blocked by hot melt glue.

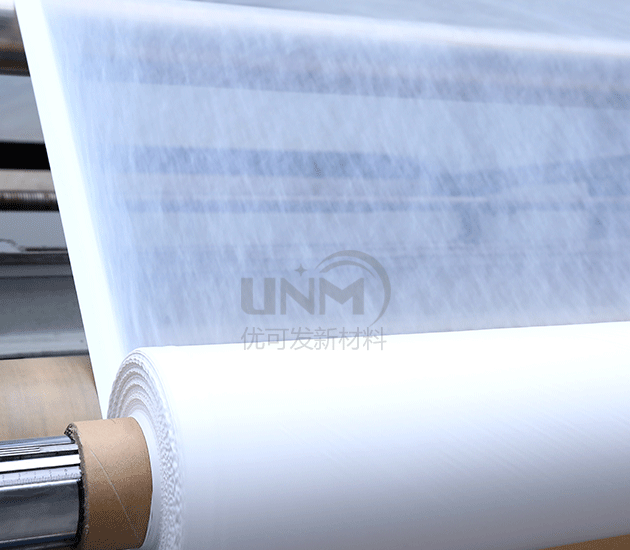

TeflonWaterproof and Breathable Membrane is a microporous membrane made by calendering, extrusion, and biaxial stretching. The porosity can reach more than 85%, and the air can flow smoothly. The membrane pore size is 0.2-3μm, which can effectively isolate water points, and the waterproof grade can reach IPX7 or above. Protect electronic instruments from becoming unusable due to moisture or water. Compared with other breathable filter materials, it has excellent air permeability. It is difficult to form a thick dust layer on the surface of the film, and the dust can be naturally peeled off.

It is a high-tech enterprise focusing on the R&D, production and sales of TeflonWaterproof Breathable Membrane, with a factory area of nearly 8,000 square meters. area, professional production equipment and strong scale, and we are a partner of Fortune 500 companies in the United States; the products we produce are all produced from imported raw materials, with finer molecular weight, cleaner quality, and better uniformity. Moreover, we have a full set of advanced production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. If you are interested, please enter the store for consultation.

</p