Generally, many equipment and their applications require a relatively closed sealed environment, which cannot be affected by external dust, water, and bacteria. If the design is particularly closed, under the objective conditions of changes in ambient temperature and latitude, it will cause pressure changes inside the equipment. Usually, this pressure change will produce a certain accumulation effect, which will cause damage to the equipment shell and sensitive internal components. Therefore, people generally use TeflonWaterproof and Breathable Membrane to continuously balance the pressure difference of the equipment, reduce component design costs, and ensure product reliability and performance.

It is understood that this process was first used in sanitary napkins, diapers, and protective clothing. At present, almost all domestic manufacturers use this process to produce highly breathable waterproof and breathable materials. The disadvantage is that the air permeability is relatively low, because the micropores of the middle breathable film are actually blocked by hot melt glue.

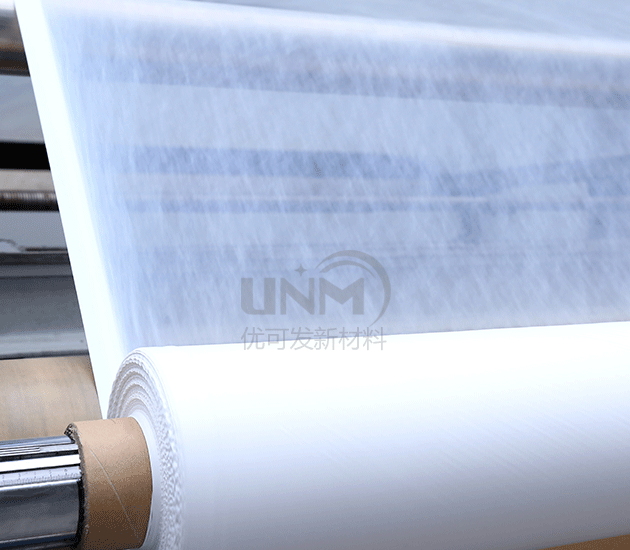

TeflonWaterproof and breathable membraneThe porosity can reach more than 85%, allowing the air to flow smoothly. The membrane pore size is 0.2-3μm, which can effectively isolate water points, and the waterproof grade can reach IPX7 or above. Protect electronic instruments from becoming unusable due to moisture or water. Compared with other breathable filter materials, it has excellent air permeability. It is difficult to form a thick dust layer on the surface of the film, and the dust can be naturally peeled off.

The Teflonwaterproof breathable membrane produced has strong hydrophobicity, chemical resistance, waterproofness and low wind resistance, and can Achieve high dust removal efficiency. For some extremely fine particles with a diameter of 0.1um-0.3um, the filtration level can reach H13-U16. In addition, biaxially stretched film can intercept various types of dust generated during the production process of enterprises. Interested parties can enter the store for consultation and purchase!

</p