Fuel cells are a new type of energy technology that directly convert the chemical energy of fuel into electrical energy through electrochemical reactions and are not restricted by geographical and geographical conditions. What we are going to talk about today is a core component in this fuel cell, which is the polytetrafluoroethylene proton membrane.

Proton exchange membrane (PEM), also called proton membrane or hydrogen ion exchange membrane, is a A dense ion-selective permeable membrane. The main internal components of the PEM water electrolyzer are, from inside to outside, the proton exchange membrane, cathode and anode catalytic layers, cathode and anode gas diffusion layers, cathode and anode end plates, etc.

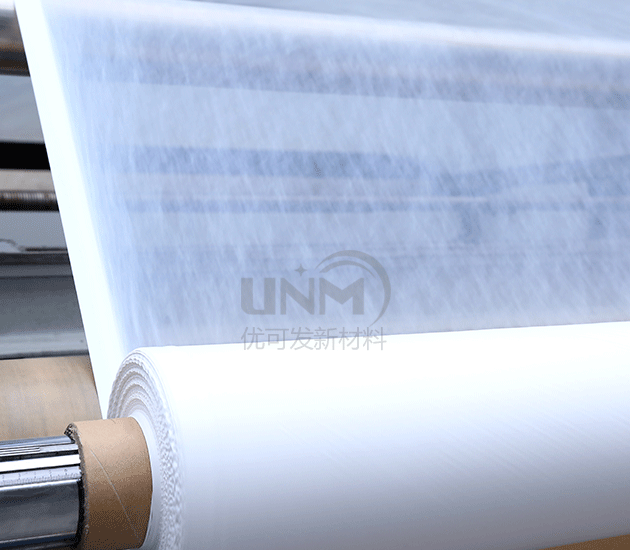

Polytetrafluoroethylene proton membrane is prepared using biaxial stretching technology, which can ensure the complete retention of impurities such as bacteria and has a relatively high Large throughput. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. The porosity can reach more than 88%, with 1.4 billion micropores per square centimeter and a pore diameter ranging from 0.1μm to 0.5μm. Generally, this film is coated on various fabrics and substrates using special processes to become a new filter material.

It is a polytetrafluoroethylene proton membrane manufacturer that specializes in R&D, production and sales. The materials of the products produced by our company are all imported raw materials, with high uniformity, stable performance and good breathability. It also has high filtration efficiency and can meet the filtration efficiency level requirements of sub-high efficiency, high efficiency and ultra high efficiency filters. We have a complete set of advanced production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. If you are interested, please enter the store for consultation.

</p