Coating technology, such as temperature, heating roller surface temperature, time longitudinal temperature difference, coating speed, upper and lower roller pressure, and even roller surface material will directly affect the fastness of the retroperitoneal filter material Overall performance such as strength, breathability, appearance, etc., and this one-time processing technology that cannot be reworked and repaired, that is, ptfe coated filter material, its own processing technology and experience are particularly important.

The international research and development of high-temperature resistant synthetic fibers started in the 1970s. Many well-known companies in the chemical industry such as DuPont of the United States, Teijin Corporation of Japan, German companies such as BASF have successively invested a large amount of R&D funds and made progress. The high-temperature resistant fibers currently widely used in the market include aramid (such as Nomex, etc.), polyphenylene sulfide (PPS), polybenzimidazole (PBI), polyimide (PI) and polyacrylonitrile pre-oxidized Fiber (PAN0F) and so on.

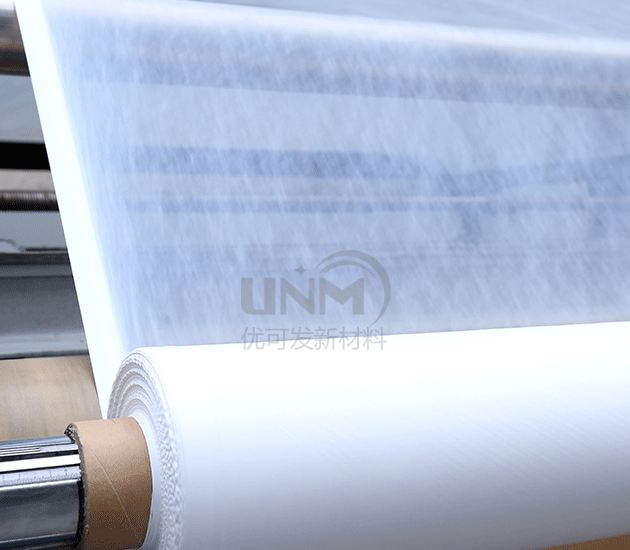

PTFE coated filter materialThe coating process is a surface processing process after printing, also known as post-printing Overmolding, post-printing lamination or post-printing lamination refers to using a laminating machine to cover the surface of the printed product with a layer of 0.012~0.020mm thick transparent plastic film to form a paper-plastic product processing technology. Generally speaking, it can be divided into two types: ready-coated film and pre-coated film according to the process used. According to the different film materials, it can be divided into two types: bright film and matte film.

It is a ptfe coated filter material manufacturer that integrates production, sales and customization. The company has advanced PTFE film production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. Interested parties can enter the store for consultation.

</p