Using the characteristics of polytetrafluoroethylene plastic resin, the ptfe gray base tape film made by biaxial stretching method has outstanding excellent performance. There can be more than one billion micropores per square centimeter on the surface. Let’s take a look at the details below.

In the 1940s, German architects discovered the self-adhesiveness and sealing properties of asphalt waterproofing membranes and coating waterproofing materials. Characteristics, the residual moisture in the concrete structure is trapped within the structure, and the water vapor in the concrete structure cannot be dispersed, causing mold to breed on the roof and walls, posing a serious threat to indoor air quality and human health. Therefore, the German construction industry began to use breathable roof underlayment to replace self-adhesive membranes and waterproof coatings. This breathable underlayment is laid on top of the roof base to quickly discharge water vapor from the cast-in-place concrete roof panels. out, thus avoiding the breeding of mold.

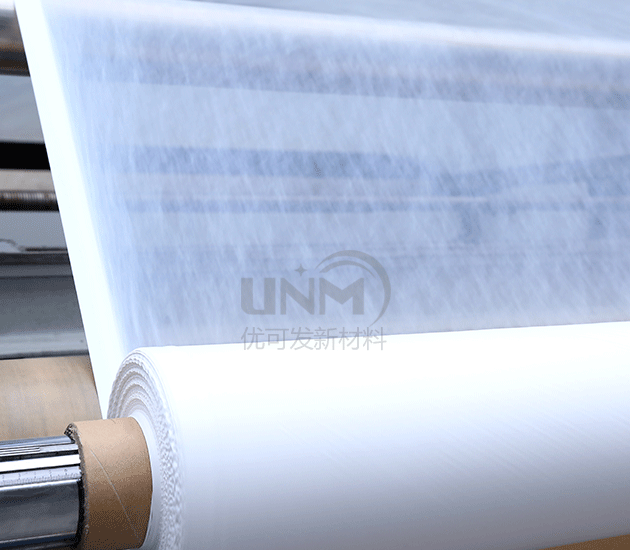

ptfe gray base membraneThe filter material has a surface filtration mechanism, the filtration efficiency can reach 99.999995%, and the porosity can reach 80%~90 %, and the material has undergone high-temperature heat setting treatment, the microporous structure is stable, and it can also effectively intercept dust particles. Therefore, it is widely used in air filtration, electronic appliances, chemical industry, machinery, construction, textile and many other fields.

It is a ptfe gray base film manufacturer that integrates production, sales and customization. The company has advanced PTFE film production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. Interested parties can enter the store for consultation.

</p