Industrial dust removal has always been an issue that factories and companies attach great importance to, especially cement plants, steel plants, power plants and other factories that generate large amounts of dust. Industrial dust removal is generally used. Dust cartridge filter bags are used to collect dust, protect personnel health and maintain the quality of manufactured products.

Just like the film-coated filter cartridge, this is a new type of product. Its use achieves better smoke and dust separation. Allow the machinery to operate normally in an environment with a relatively stable degree of cleanliness, thereby avoiding problems caused by the dust environment affecting the normal operation of the machinery. The foundry industry, with its resource-intensive, energy-intensive, large-scale production and large logistics throughput characteristics, has long been regarded as an enterprise with large emissions of smoke, waste, and pollution. For this reason, many enterprises in this field will be Bag dust removal technology is used to solve the emission problem, and the polytetrafluoroethylene dust removal membrane plays an important role here.

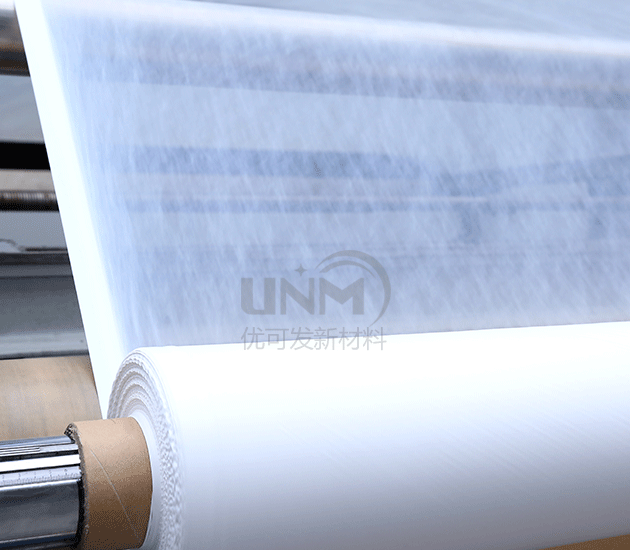

The currently independently developed polytetrafluoroethylene dust removal membrane is the core raw material of industrial dust removal filter cartridges and filter bags. It has the characteristics of good durability, reusability, good pulse dust removal effect, and high cost performance.

It is a fluorine material film manufacturer integrating production, sales and customization. The company has advancedPTFE dust removal membrane production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. Interested parties can enter the store for consultation.

</p