At present, my country’s industrial pollution is a large source of PM2.5. Among them, cement manufacturing, coal-fired power stations and steel metallurgy are the three major killers of industrial pollution sources. Therefore, PM2. 5. Industrial dust removal cannot be ignored. However, industrial dust removal is not easy. This is because industrial smoke has a high temperature and often contains acidic and alkaline gases, which places high requirements on the technology and materials used in industrial dust removal.

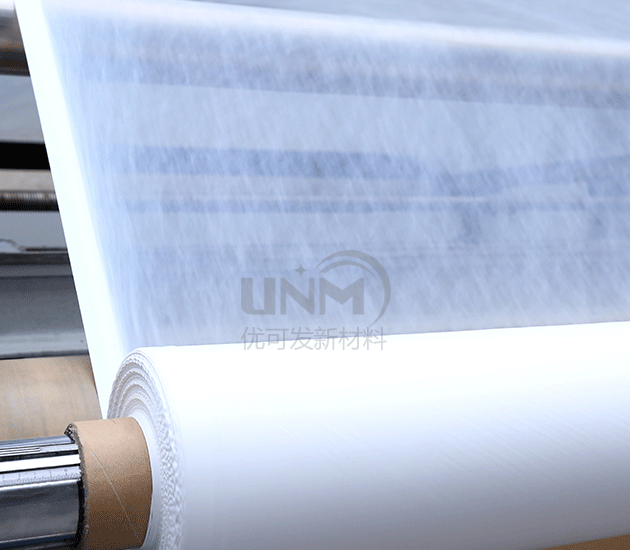

Teflon high-temperature membraneThe pore size can be between 0.1 and 0.1- 1um, the thickness can be between 10-100um, the porosity can reach 50%-90%, and there are hundreds of millions of micropores per square centimeter. Since the pore size of the microporous membrane is much larger than that of water vapor molecules, and the operating temperature can reach -150℃-250℃, the Teflon high-temperature membrane has excellent corrosion resistance, aging resistance, and temperature resistance. This membrane is currently used on the market. Wide range.

Teflon high temperature membrane is a polymer compound polymerized by tetrafluoroethylene, which has excellent high temperature resistance and Oxidation, alkali resistance, hydrophobicity, non-adhesion properties, the porosity can reach more than 88%, or even higher, and this film has 1.4 billion micropores per square centimeter, with a pore diameter ranging from 0.1um to 0.5um. High and low temperature resistance (-200℃-260℃), no aging, no splitting, no discoloration, and strong weather resistance after long-term use.

Suzhou New Material Technology Co., Ltd. is a company integrating ptfe air filter membrane, ptfe bubble point membrane, Teflon high temperature membrane, special A fluorine material film manufacturer that integrates the research, development, production and sales of fluoron membranes and membrane-coated filter materials. The company has advanced PTFE film production lines, lamination and composite production lines. In addition, we can also produce according to user requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation.

</p