Clothing fabrics are generally made of PU and TPU. The breathability of this kind of fabric will decrease at low temperatures, but it is cheap and has a long service life. It has better water resistance than PTFE. Generally speaking, It is used more frequently. The filter materials of ptfe protective clothing are mostly laminated fabrics. The main principle is to stretch polytetrafluoroethylene to make micropores appear, and then layer a hydrophobic and breathable film layer under the outer fabric to achieve the effect of water repellency and breathability.

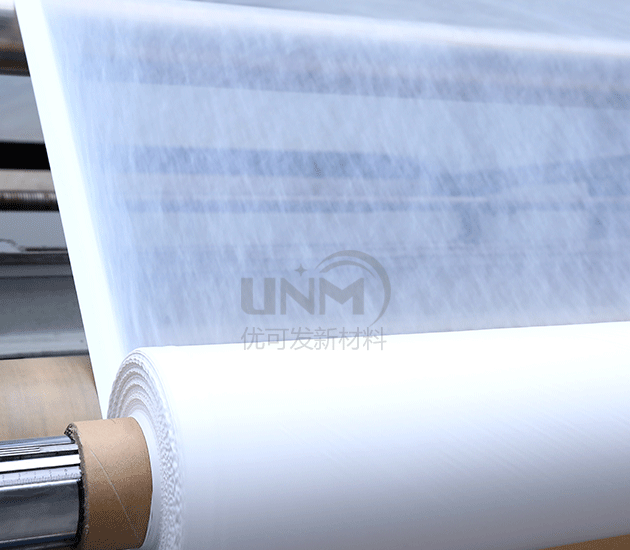

Independently produced ptfe protective clothing filter material As a protective clothing production, its main features are It is hydrophobic and breathable, with good comfort. Its hydrophobic and breathable function is to compound a layer of microporous film on the outer fabric of the garment. These micropores are evenly distributed, with small pore size and high porosity. Because the micropores are smaller than water droplet molecules and larger than gas molecules, they can evaporate their own sweat while blocking rainwater. The characteristic of this kind of fabric is that it has good stability and its performance is not easy to change even under low temperature conditions. Therefore, ptfe protective clothing filter material is often used in various harsh environments.

Suzhou New Material Technology Co., Ltd. is a company integrating ptfe air filter membrane, ptfe bubble point membrane,ptfe protective clothing filter material, a fluorine material film manufacturer that integrates the R&D, production and sales of Teflon films and coated filter materials. The company has advanced PTFE film production lines, lamination and composite production lines, which are at the domestic advanced level. The company’s products are widely used in various fields, and we have a complete pre-sales, sales and after-sales service system. Interested parties can enter the store to consult us.

</p