PTFE proton membraneThe main application is fuel cells. A fuel cell using a proton exchange membrane is called a proton exchange membrane fuel cell, which shows the important position of the proton exchange membrane in this type of fuel cell. Fuel cells can convert chemical energy into electrical energy. Compared with traditional energy utilization methods, fuel cells have the advantages of high conversion efficiency, high energy density, high power density, low noise, and environmental protection without pollution. Fuel cells can be used in aerospace, portable power, transportation, stationary power generation and other fields.

Generally speaking, materials can be divided into three categories according to their conductivity: conductors, semiconductors and insulators. By definition, a conductor is a material that can conduct electrical current. Electric current is formed by the movement of electric charges. In addition to electrons, the carriers of electric charges also include various types of ions. Conductors that can conduct electrons are called first-class conductors, and conductors that can conduct ions are called second-class conductors. . A proton exchange membrane is a type II conductor that can conduct protons.

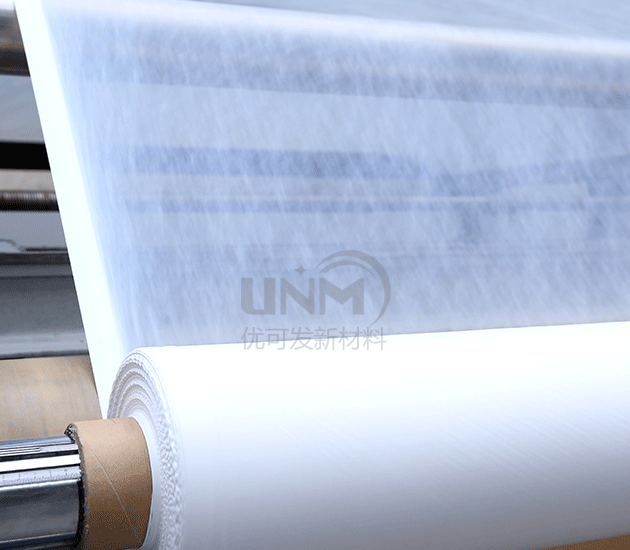

Proton exchange membrane is a type of thin film material with a thickness of about tens to hundreds of microns. Polytetrafluoroethylene proton membrane is similar to The diameter of a human hair is similar. The proton exchange membrane has the following two basic requirements: Like the basic functions of other membrane materials, the proton exchange membrane also needs to have good isolation capabilities, that is, except for protons, other substances cannot pass through, including electrons. and gas molecules; secondly, the proton exchange membrane needs to have good proton conductivity. Generally speaking, the proton conductivity needs to be above 0.1S/cm. This is like a highway, which not only requires strict control of passing vehicles, but also requires high speed and efficiency.

Fuel cells are a promising energy utilization technology, and the fuel cell industry is booming around the world. With the development of the fuel cell industry, the development of key fuel cell materials has also followed suit, and proton exchange membrane materials have therefore been extensively developed and researched. At present, proton exchange membranes are moving towards high performance, high durability and low cost.

Polytetrafluoroethylene proton membrane is located in the center of the membrane electrode. It is the core component of the proton exchange membrane fuel cell and serves to separate the fuel. The performance and life of the proton exchange membrane directly determines the performance and life of the battery due to the role of oxidant, conductive protons and insulating electrons. Because increasing the battery operating temperature can not only speed up the electrocatalytic oxidation of methanol, reduce the penetration of methanol, reduce poisoning of precious metal catalysts, and simplify water management.

The manufacturer’s product is polytetrafluoroethylene proton membrane, which is polymerized by polytetrafluoroethylene. It adopts a special process and is calendered and Microporous membranes made by extrusion, biaxial stretching and other methods. The film also has excellent corrosion resistance, aging resistance and temperature resistance, and the operating temperature can reach -150℃-250℃. It has been widely used in many fields such as electronics, chemical industry, medicine, military, aerospace, clothing, environmental protection and so on. Interested parties can enter the store for consultation.

</p