Many companies will have dust pollution problems during the production process, and companies need to pay attention to and deal with them. Therefore, equipping dust removal equipment has become the choice of many companies, and Teflon high-temperature membraneis the core component of dust removal equipment.

With the development of my country’s economy and society, people’s requirements for the living environment are getting higher and higher. Energy, chemical, steel and other industries generate nearly 10 million tons of dust every year, which has serious impacts on human health, atmospheric environment and production economy. In particular, the large amount of smoke emitted by coal-fired power plants is almost all inhalable particulate matter (PM10 and PM2.5), which is very harmful to human health. At present, the methods that can effectively remove dust particles in high-temperature flue gas mainly include cyclone dust collectors, electrostatic precipitators, bag dust collectors, cartridge dust collectors, etc. Below, the Teflon high-temperature membrane manufacturer introduces the bag dust collector and its materials.

Bag dust collector. The working principle of the bag dust collector is that when the dust-containing gas enters the ash hopper from the air inlet pipe at the bottom of the dust collector through the deflector, the coarse dust will fall into the ash hopper due to the collision of the deflector and the reduction of the gas speed. When the dust-containing gas passes through the filter cloth in one direction, the dust particles enter the filter bag chamber with the gas. The bag filter cloth is made of fiber and other materials. Collision and intercepted; fine dust particles (particle diameter of 1 μm or less) are constantly changing their direction of motion due to the impact of gas molecules (Brownian motion). Since the gaps between fibers are smaller than the free path of the Brownian motion of gas molecules, the dust particles will interact with the gas molecules. The fibers are separated by collision; enough dust particles accumulate on the surface of the filter cloth fibers to form a filter cake. This filter cake can capture finer dust particles through sieving and other mechanisms. The dust particles remain in the upstream or on the dusty gas side of the filter cloth, while the clean gas passes through the filter cloth to the downstream or clean gas side. When the dust particles are deposited to a certain extent, the dust particles are removed from the filter cloth with the help of pneumatic or mechanical methods. Remove, collect and haul away.

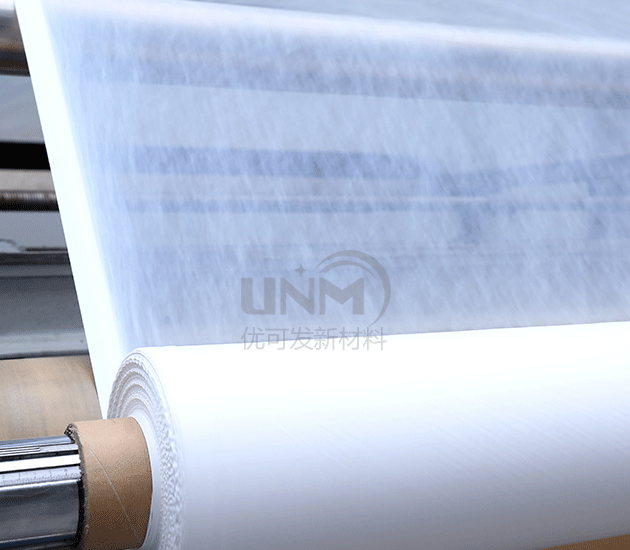

Teflon high-temperature membrane is the core filter material of the bag dust collector. The opening rate and pore size distribution are important to measure the PTFE membrane. index. The opening rate of Teflon high-temperature membrane is generally between 80% and 95%. A high opening rate will increase ventilation; a concentrated pore size distribution indicates that the membrane pore size is uniform. It also has good filterability for special gases with high temperature, high humidity, high corrosion and organic liquids. Relying on the special production process of Teflon high-temperature membrane, the company can control different pore sizes for different materials to achieve the purpose of purification and filtration. Interested parties can enter the store for consultation and purchase!

</p