Generally speaking, ordinary people rarely see FFU, but we use high-precision instruments such as iPhones, SLR optical lenses, display screen panels, computer chips, and some biological Scientific experiments need to be produced in a highly clean environment. In this environment, there are applications of FFU and Clean room FFU filter membrane materials.

FFU is a modular terminal air supply device with a built-in fan and air filtration efficiency. The fan sucks air in from the top of the FFU After passing through the HEPA filter, the filtered clean air is evenly sent out on the entire air outlet surface at a wind speed of 0.45m/s. It provides high-quality clean air for clean rooms and micro-environments of different sizes and cleanliness levels. In the clean factory-style renovation of a new clean room, it can improve the cleanliness level, reduce noise and vibration, and greatly reduce operating costs. It is easy to install and maintain. It is an ideal purification air supply unit for clean rooms.

As a separation filtration material design solution provider, we are committed to protecting personnel and processes by developing and producing high-quality PTFE air filtration membranes and composite materials. and system. At present, the independently developed Clean room FFU filter membrane is widely used in the field of air filtration, such as: vacuum cleaner filters, clean room filtration, personal protection, etc., as well as industrial dust removal, such as industrial dust removal filter cartridges On the production of filter bags. It has high filtration efficiency and has the reliable grade filtration efficiency of H13-U16.

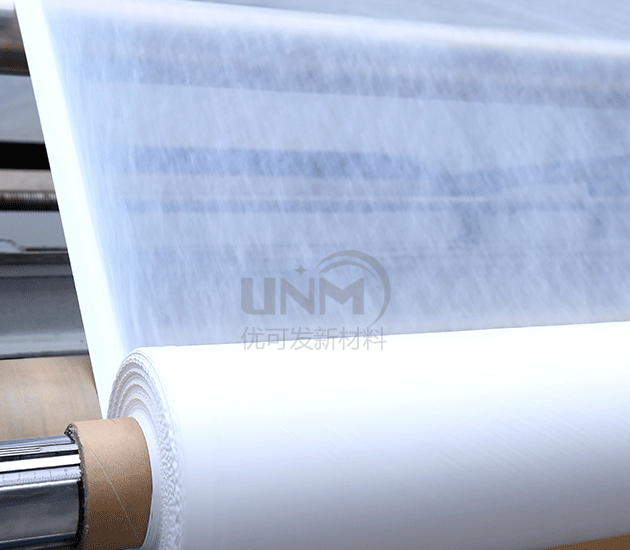

Clean room FFU filter membrane refers to the use of polytetrafluoroethylene as raw material, using special processing technology, through calendering, extrusion, A microporous film and non-woven fabric made by biaxial stretching and other methods. This kind of membrane has excellent breathability, corrosion resistance, aging resistance and other properties. According to the usage requirements, the pore diameter can be between 0.1-1um, the thickness can be between 3-70um, the porosity can reach 85%-90%, and there are up to hundreds of millions of micropores per square centimeter. Because the micropore diameter is tens of thousands of times that of water molecules and hundreds of times smaller than water droplets, it has excellent moisture permeability, air permeability and hydrophobicity. Interested parties can enter the store for consultation and purchase!

</p