PTFE film has a smooth surface, good density, and high porosity, which facilitates the deposition of particles on the film surface. When the accumulation reaches a certain level, the particles will fall off due to gravity, achieving surface filtration. ptfe microporous filter membrane The filter material has the advantages of good filtration performance and long service life. Therefore, more and more manufacturers are beginning to produce this new type of filter material.

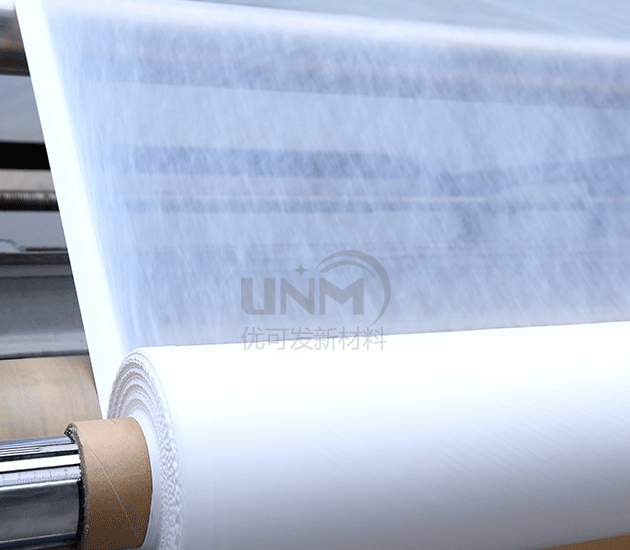

This kind of film is generally produced by a biaxial stretching process. The biaxial stretching method was invented by DuPont. When the processing temperature is between the glass transition temperature and the melting point of the polymer, micropores can be produced by stretching the polymer sheet in both transverse and longitudinal directions, while maintaining the tensile load. Cool down and the shape of the micropores can be fixed. Among the biaxially oriented films that have been marketed, polytetrafluoroethylene (ptfe) films account for the vast majority.

The ptfe microporous filter membrane independently developed by New Material Technology Co., Ltd. is made using a special biaxial stretching process. Moreover, the pore size of the material is small and the distribution is concentrated, achieving surface filtration to achieve a dust removal efficiency of 99.9%~99.999%. For some very small particles with a diameter of 0.1um-0.3um, it can well prevent fine dust from entering the filter material. It can operate at a continuous operating temperature of 240°C and an instantaneous temperature of 260°C.

The air filter made of ptfe microporous filter membrane has good filtration performance, low pressure loss, and large dust holding capacity. Remarkable features such as long service life. This filter membrane can effectively capture particles above 0.3μm, with an efficiency of over 99.99%. There is also PTFE-coated filter material containing bacteriostatic (bactericide), which can effectively inhibit the growth of microorganisms in the filter material, prevent secondary pollution of the filter, and thus achieve the purpose of protecting the environment. Interested parties are welcome to enter the store for consultation.

</p