The color fastness of textiles, also called dye fastness, refers to the ability of colored textile products to resist various external effects without discoloration. The following describes the analysis and detection methods of textile color fastness.

Analysis of color fastness of textiles

Usually expressed in two ways: discoloration series and staining series (color fastness to light) Except for degree):

The discoloration grade indicates the degree of change in brightness (depth), saturation (brightness) and hue (color light) of the sample after treatment;

The staining grade indicates the degree of contamination of adjacent fabrics caused by the sample during the treatment process.

The higher the discoloration level and staining level, the better the color fastness, which means the stronger the textile’s ability to resist discoloration or staining.

The most basic color fastness items are: resistance to rubbing, washing, perspiration, saliva, sunlight, water, ironing, bleaching, and light and sweat resistance. etc.

Purpose

Dyes and finishing agents are used in the printing and dyeing process of textiles and various processing aids and other chemicals, and many other substances are harmful to the human body.

During use, textiles will be affected by various external effects such as light, washing, ironing, sweat stains and chemicals. If their color fastness is poor, on the one hand some parts Dyes or finishing agents will be decomposed or reduced to harmful groups under the biological catalysis of human sweat and saliva proteins, which will be absorbed by the human body and accumulate in the body, causing harm to human health; on the other hand, during the dyeing process or When consumers wash, the dyes and finishing agents that fall off due to poor color fastness are discharged into rivers along with wastewater, which will also have an adverse impact on the environment. Therefore, the color fastness of textiles is not only an important quality indicator, but also an important ecological and technical indicator.

Ecological and environmental protection requirements

In recent years, in the international textile and apparel trade, color fastness In addition to ensuring the quality of the product, we also constantly pay attention to its safety and environmental protection.

Currently, countries are using laws, regulations, standards and other forms to continuously put forward new limit indicators for harmful substances related to human health and environmental protection in textiles. Color fastness is one of them. .

The color fastness requirements of the International Textile Association standard are: water resistance, perspiration resistance, dry friction resistance and saliva resistance.

The color fastness required by the EU Eco-Textile Mark is based on the International Textile Association standards and adds color fastness to wet rubbing and sunlight resistance.

Colors in nature are generally described by three attributes:

❖Hue: the appearance of a color, which is the quantity that expresses the color attributes.

❖Chroma: also known as saturation, refers to the purity of a color. Associated with the vividness of color.

❖Brightness: Also known as brightness, it indicates the intensity of light reflected from the surface of a colored object. Relevant to the shades of color.

General rules for color fastness testing of textiles

1. Types of backing fabrics

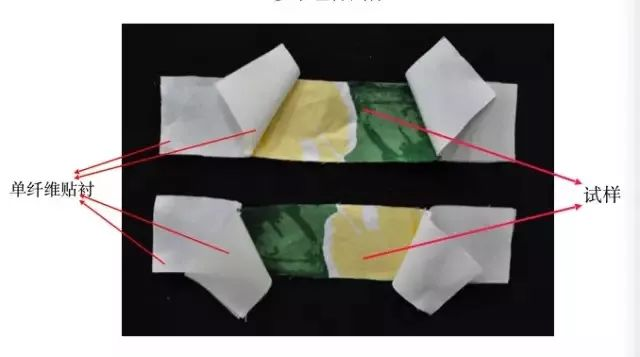

❖Single fiber lining:

Wool, cotton and viscose, polyamide, polyester, polyacrylonitrile, silk fiber

❖Multi-fiber lining:

Acetate fiber, bleached cotton, polyamide fiber, polyester fiber, polyacrylonitrile fiber, wool

2. Size and use of lining fabric

❖Two pieces of single fiber lining:

The first piece is made from the same fiber of the sample, and the second piece is made according to the test method. If the sample is a blended or interwoven product, the first piece shall be made of fibers with a major content and the second piece shall be made with a minor content of fibers.

Both sides of the specimen shall be completely covered with a backing fabric.

The size is the same as the sample, generally 40 (mm) X100 (mm).

A multi-fiber backing:

Cover only the front side of the specimen. The size is the same as the sample, which is also 40 (mm) x 100 (mm).

Single combined sample

Multiple combination samples

3. Humidity control

❖The sample and the backing fabric generally do not require special humidity control.

However, if the difference in moisture content between the sample and the backing fabric will affect the test results, all fabrics should be in accordance with GB/T6529 “Standard Atmosphere for Humidity Conditioning and Testing of Textiles” Humidity is adjusted under the specified standard atmospheric environment.

❖GB/T6529-2008 standard atmospheric environment:

Temperature 20±2℃,

Relative humidity 65±4%

4. Test solution

❖Test The liquid must be prepared with third-grade distilled water that complies with GB/T6682 “Specifications and Test Methods for Water Use in Analytical Laboratories”.

5. Evaluation of color fastness

❖Gray sample card for discoloration

➢The gray sample card for discoloration is five levels and nine levels, with five whole levels of color fastness levels 5, 4, 3, 2, 1; add one and a half grades to each two grades, namely 4-5, 3-4, 2-3, 1-2.

➢When the visual color difference between the original sample and the tested sample is equivalent to the visual color difference of a certain grade of gray sample card (or close to between two grades), This grade is regarded as the color fastness grade (or intermediate grade) of the sample.

Gray sample card for staining-GB/T251

Stain fastness rating

❖Use gray sample card for color change

➢The gray sample card for discoloration is five levels and nine levels. There are five whole levels of color fastness levels 5, 4, 3, 2, and 1; in each two levels Add another half level, namely 4-5, 3-4, 2-3, 1-2.

➢When the visual color difference between the original sample and the tested sample is equivalent to the visual color difference of a certain grade of gray sample card (or close to between two grades), This grade is regarded as the color fastness grade (or intermediate grade) of the sample.

Gray sample card for discoloration-GB/T251

Discoloration Fastness rating

Color fastness to perspiration

Testing process

❖Inspection basis:

GB/T3922-1995 “Test Method for Textile Color Fastness to Perspiration”.

❖Testing principle:

Combine the textile sample with the specified backing fabric and place it on a surface containing histidine In acid and alkali solutions, after separate treatment, remove the test solution and place it between two flat plates with specified pressure in the test device, and then dry the sample and the backing fabric separately. Use the gray sample card to evaluate the discoloration of the sample and the staining of the backing fabric.

❖Instrument equipment:

➢At least two stainless steel racks;

A weight of approximately 5 (kg) with a bottom area of 115 (mm) × 60 (mm) (including spring pressure plate);

The size is approximately 115 (mm) × 60 ( mm), a glass plate or acrylic resin plate with a thickness of 15 (mm);

A combined sample of 40 (mm) × 100 (mm).

The instrument structure should ensure that the sample is under pressure of 12.5KPa.

➢Constant temperature incubator, temperature environment (37±2)℃, no ventilation device.

❖Operation steps:

1. Selection of lining fabric: one piece of multi-fiber lining fabric or two pieces of single fiber lining Lining fabric. If single fibers are used, the first single fiber backing shall be made of fibers of the same type as the specimen and the second single fiber backing shall be made of fibers specified in the table below.

2. Sample preparation: Take a 40 (mm) × 100 (mm) sample, and the front side and a 40 (mm) × 100 ( mm) multi-fiber lining fabric is in contact with or sandwiched between two 40 (mm) × 100 (mm) single fiber lining fabrics.

Color fastness to water

Detection process

Color fastness to saliva

❖Inspection basis: GB/T18886-2002 “Textiles Color Fastness Test to Saliva Color Fastness”

❖Testing principle: Combine the textile sample with the specified Put the adhering fabrics together, treat them in artificial saliva, remove the test solution, place them between two flat plates in the test device and apply the specified pressure, then dry the sample and the adhering fabrics separately, and use the gray sample card to evaluate the samples discoloration and staining of the backing fabric.

Color fastness to rubbing

❖Inspection basis: GB/T3920-2008 “Color Fastness to Rubbing Test for Color Fastness of Textiles”

❖Testing principle: Place the textile sample with a dry rubbing cloth or wet Rub with a friction cloth and evaluate the staining degree of the friction cloth.

❖Instrument and device: color fastness to rubbing tester

Circular friction head

Square friction head

❖Operation steps:

1. Sample preparation: Prepare a set of sizes not less than 50 (mm) × 140 (mm) two specimens each.

➢The length of one sample is parallel to the warp yarn (or longitudinal direction), and the length direction of the other sample is parallel to the weft yarn (or transverse direction).

➢If the pile layer of the carpet is easy to identify, the direction of the pile when cutting the sample should be consistent with the length of the sample.

2. Preparation of friction cloth:

Circular friction head: (50±2×50±2) (mm) Square

Rectangular friction head: (25±2×100±2) (mm) Rectangle

3. Sample and friction cloth Humidity adjustment: Place the sample and friction cloth in the standard atmosphere specified in GB/T6529 to adjust the humidity for at least 4 hours.

4. Operation procedure: Place the humidity-adjusted friction cloth on the friction head so that the warp direction of the friction cloth is consistent with the running direction of the friction head. The operating speed is 1 reciprocating cycle friction per second, with a total of 10 cycles of friction. Remove the rubbing cloth and moisturize it.

.png”>

Color fastness to rubbing

❖Inspection basis: GB/T3920- 2008 “Textiles Color Fastness Test – Color Fastness to Rubbing”

❖Testing principle: Rub the textile sample with a dry or wet rubbing cloth to evaluate the staining of the rubbing cloth. Degree.

❖Instrument and device: color fastness to rubbing tester

Round friction head

Square friction head

❖Operation steps:

1. Sample preparation: Prepare a set of different sizes Two samples each smaller than 50 (mm) × 140 (mm).

➢The length of one sample is parallel to the warp (or longitudinal), and the length of the other sample is The length direction is parallel to the weft yarn (or transverse direction).

➢If the pile layer of the carpet is easy to identify, the direction of the pile when cutting the sample should be consistent with the length direction of the sample.

2. Preparation of friction cloth:

Circular friction head: (50±2×50±2) (mm) square

Rectangular friction head: (25±2×100±2) (mm) rectangle

3. Sample and friction cloth Humidity adjustment: Place the sample and friction cloth in the standard atmosphere specified in GB/T6529 to adjust humidity for at least 4 hours.

4. Operation procedure: Place the humidity-controlled friction cloth on On the friction head, make the warp direction of the friction cloth consistent with the running direction of the friction head. The running speed is 1 reciprocating speed per second for 10 cycles of friction. Remove the friction cloth and adjust its humidity.</p